For plastic injection molding machines, the larger the tonnage is, the harder and longer the mold changing process is. But with quick mold change system, everything is different.

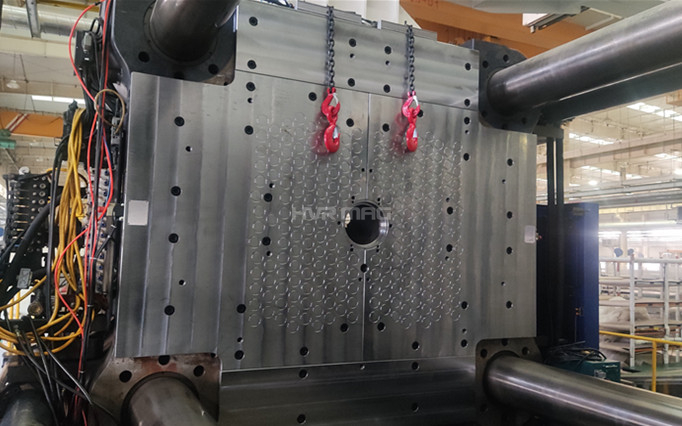

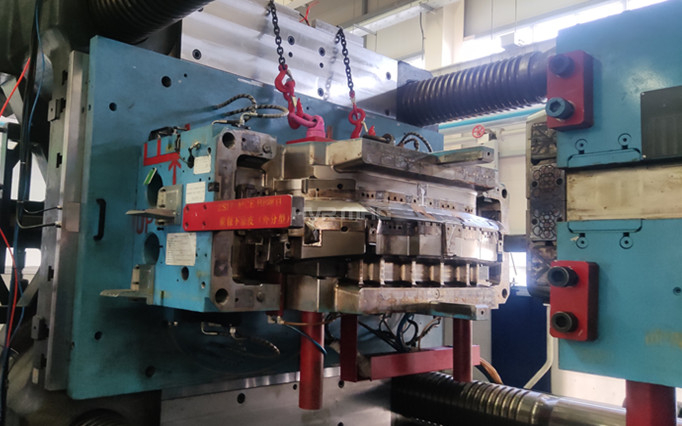

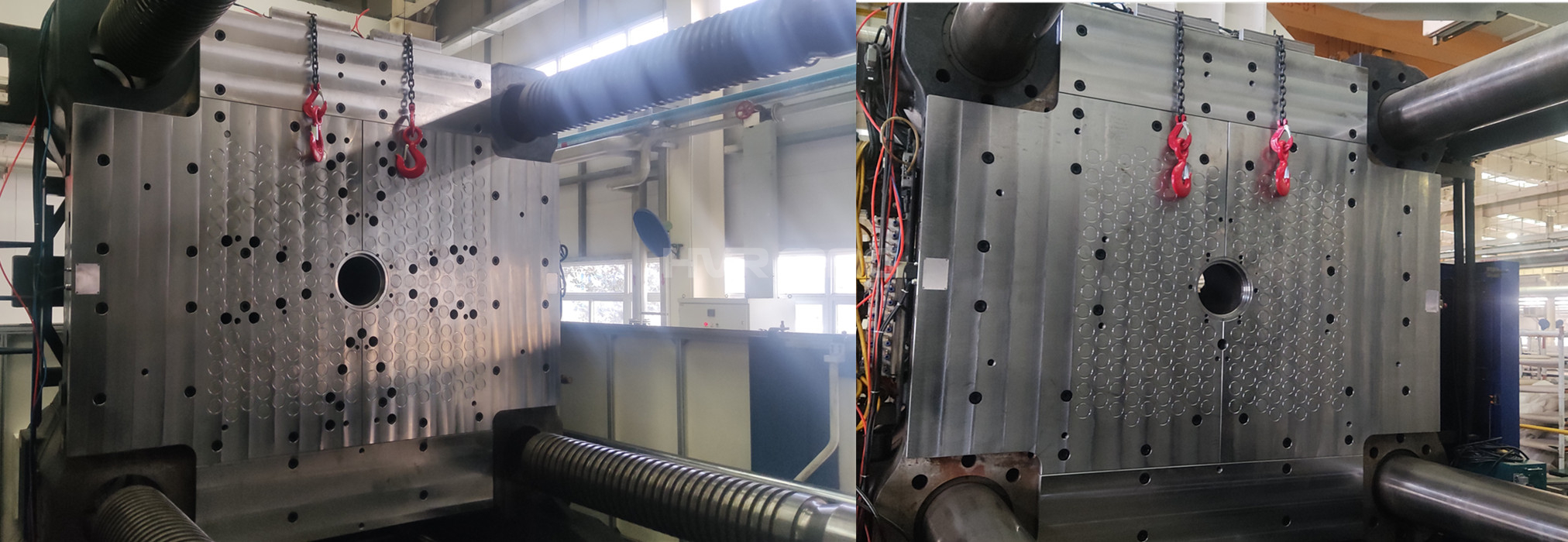

Check the new installation of quick mold change system, supplied by HVR MAG, on a 3300 ton Haitian injection molding machine, to reduce the changing time of molds, in a bus manufacturing company.

But with our magnetic quick mold change system installed, all these concerns are addressed, with extra benefits:

✦Uniform magnetic clamping force on the mold, less risk of mold distortion caused by mechanical clamping

For more further technical info or other queries about our quick mold change system, please contact us for customization and quotation.

Work directly with our experienced team to solve your toughest engineering challenges