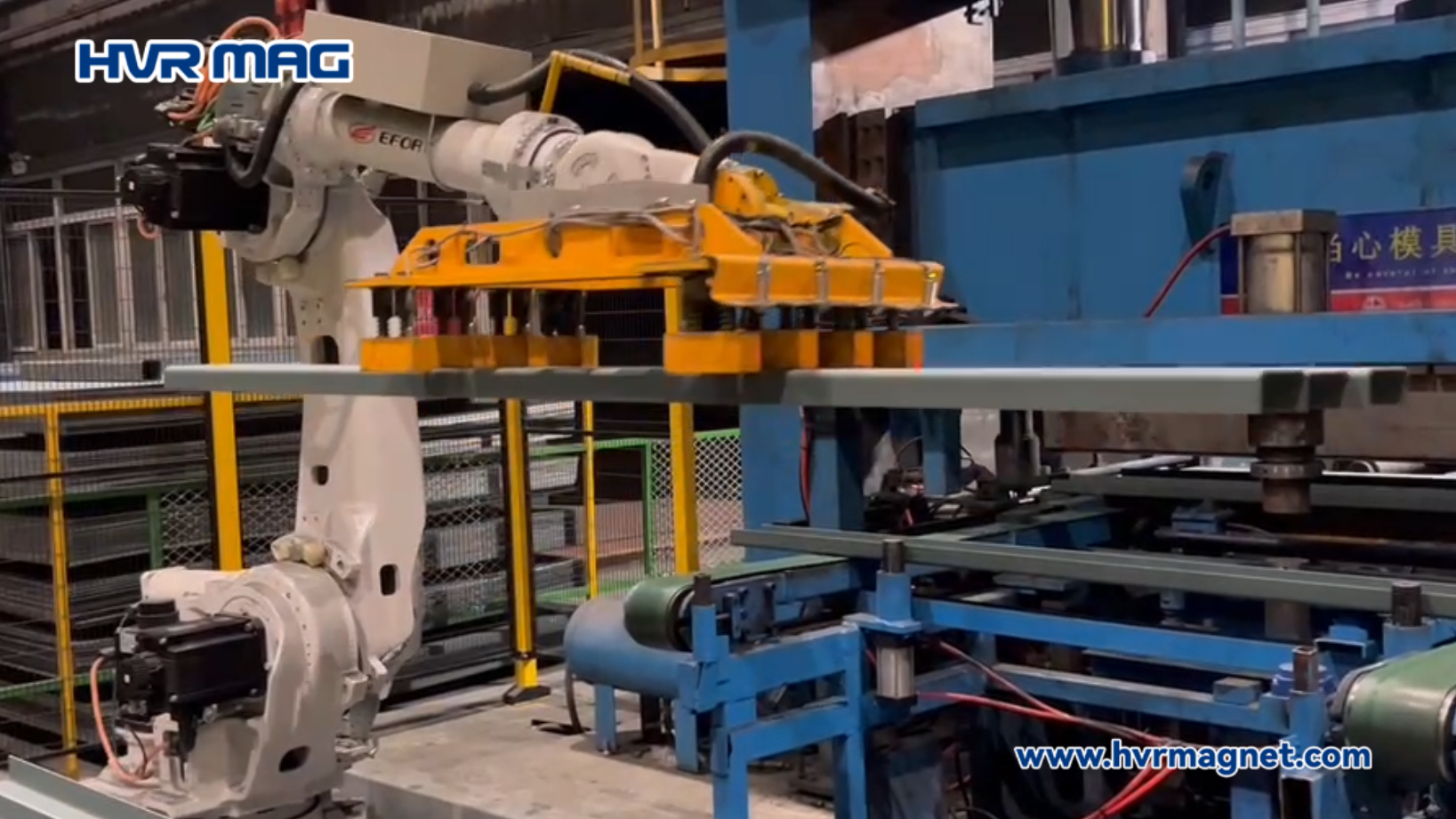

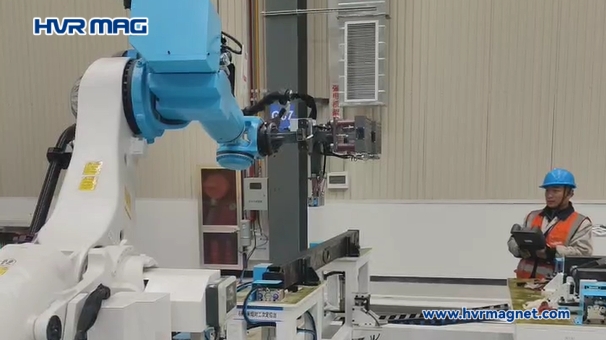

Construction machinery manufacturing relies heavily on the efficient handling of heavy steel materials. Traditional methods of lifting and moving these materials, such as using cranes and manual labor, can be time-consuming, labor-intensive, and potentially dangerous. However, with the advancement of technology, there is a better solution available: electro

Read more »