For now, the most efficient way to handle steel plates or steel part is to use magnet, especially electro-permanent magnet. This is mainly because of its high efficiency of ferrous material handling, high safety and energy efficiency, and no scratches left on the product surface. Here is an application case of magnetic grippers for structural steel palletizing in an intelligent plant of Sany Heavy Machinery.

1. Automated robotic arm grippers have low demands for the steel parts. As long as it is a ferromagnetic material, magnetic grippers have no harsh requirements for the surface flatness (general air gap of about 2mm), which is different from vacuum grippers.

2. Magnetic end effectors can replace repetitive manual work, reduce labor intensity, and improve production efficiency.

3. Robotic magnetic grippers can work 24 hours non-stop, with modular movement, near-zero mistakes, and PLC system controlled.

4. When the automated magnetic end effectors handle the steel structure, they only need to adsorb the surface of the workpiece, so it will not cause scratches on the workpiece. This dramatically improves the product yield.

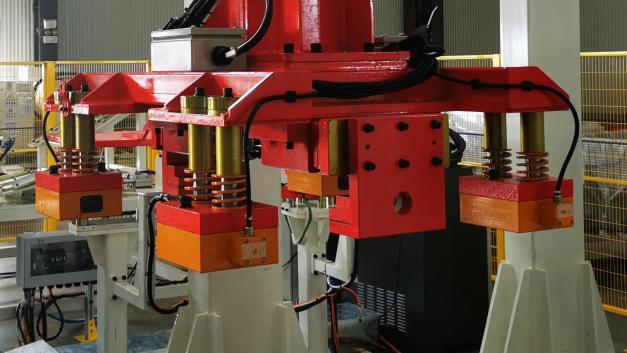

The magnetic grippers with various sizes, in conjunction with industrial robots, can ensure correct palletizing of steel products.

Automated magnetic end effectors on industrial robots: the magnetic force can be adjusted by the controller to carry out flexible handling.

HVR MAG wins respect with service and establishes authority with professionalism. We will continue to help the construction and transformation of intelligent plants. If you need more information or a quotation on our magnetic grippers for structural steel, please send e-mails to: export@hvrmagnet.com