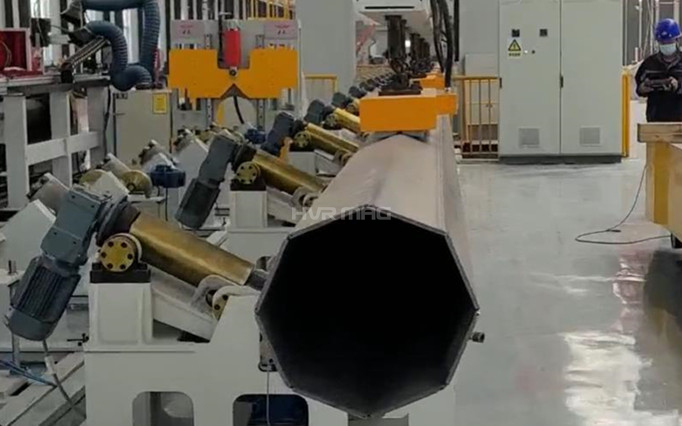

Most often lifting magnets are working below the hook of overhead crane, to move and transfer steel material. But in automation, magnet lifters are also frequently used in gantry system for automatic transferring of steel products, like octagonal steel tube mentioned below.

Specifications of octagonal steel tube: length:12 m; maximum weight: 2.5 ton

Previously used lifting tool: sling/rope

The irregularly shaped surface of octagonal tube, crosses out the choice of permanent magnetic lifters. HVR MAG's magnetic lifting solution: 5pcs of HEPMSP-7717S electro-permanent magnet lifters, custom designed with

V-shaped groove, equipped on gantry system.

How Do These Magnet Lifters Work?

They use

electrically switched permanent magnetic force to lift and hold steel tube in one go. Once magnetized by an electric pulse, their magnetic force is released to grab the load, and can remain holding of the tube even in a sudden power failure or outage. This means, that the suspended tube will not fall off if the power breaks down abruptly. Moreover, no electricity is consumed during the lifting process. These magnetic lifters only use electricity in MAG and DEMAG phase to switch on/off the magnetic force.

Advantages of Magnet Lifters Over Slings/Ropes:

✦No safety hazard - strong & stable magnetic force ensures a tight gripping of the tube

✦No scratches to the surface of tube, no influence on the next processing procedure

✦Improved tube handling efficiency