With the development of industrial automation, many production activities have been replaced by robots. However, in the construction industry, such as bevel cutting and welding, the site environment and product requirements are complex and variable. The use of traditional toolings cannot meet the changing development needs.

In steel, construction, and coal mining machinery, steel plate workpieces are generally 20mm thick. Equipment such as flame and plasma are usually used to cut bevels from thick steel plates at specific angles to facilitate subsequent welding. The wide variety of steel plates and the many application scenarios such as workpiece contours with circular curves make it difficult to achieve unmanned flexible production by traditional tools.

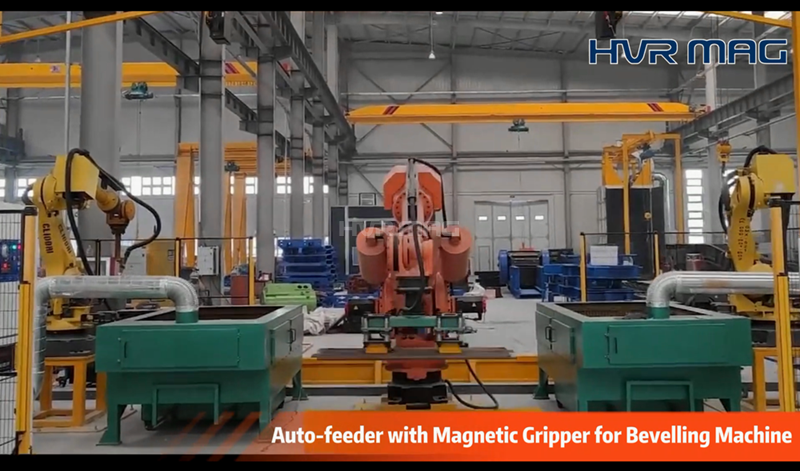

The following example in the coal mining machinery industry will help you better understand HVR magnetic grippers.

The difficulties of the project:

-Heavy workpieces, low crane lifting efficiency

-Diverse workpieces

-Complex site environment, no guarantee of machining loading&unloading, safety and results.

HVR solution advantages:

-Fully intelligent loading and unloading with the high magnetic power of the magnetic grippers, significantly increasing handling speed and reducing prep time.

-Accurate positioning and improved cutting quality

-Significantly improved ease of use and high stability of the entire process for personnel, reducing work equipment maintenance

On the one hand, HVR magnetic grippers allow manufacturers to respond quickly to the manufacturing rhythm of the coal mining machinery industry, allowing them to easily cope with the production requirements of small batches and different types of bevel cutting. On the other hand, magnetic grippers significantly improve product quality and material utilisation, meeting the expectations of innovative applications of robots in the construction sector.

The coal mining industry supply chain favours the new magnetic manipulator's intelligent automatic mode, and magnetic grippers have now successfully provided a solid boost for the construction and coal mining industries. HVR will further refine its expertise to help customers build a new competitive advantage and create a new realm of intelligent production on the road to high-quality development in the coal mining machinery industry.

If you want to be as productive as possible and increase your ROI, update/upgrade your production line. HVR magnetic gripper is flexible, and it can work for your present and future needs.

Work directly with our experienced team to solve your toughest engineering challenges