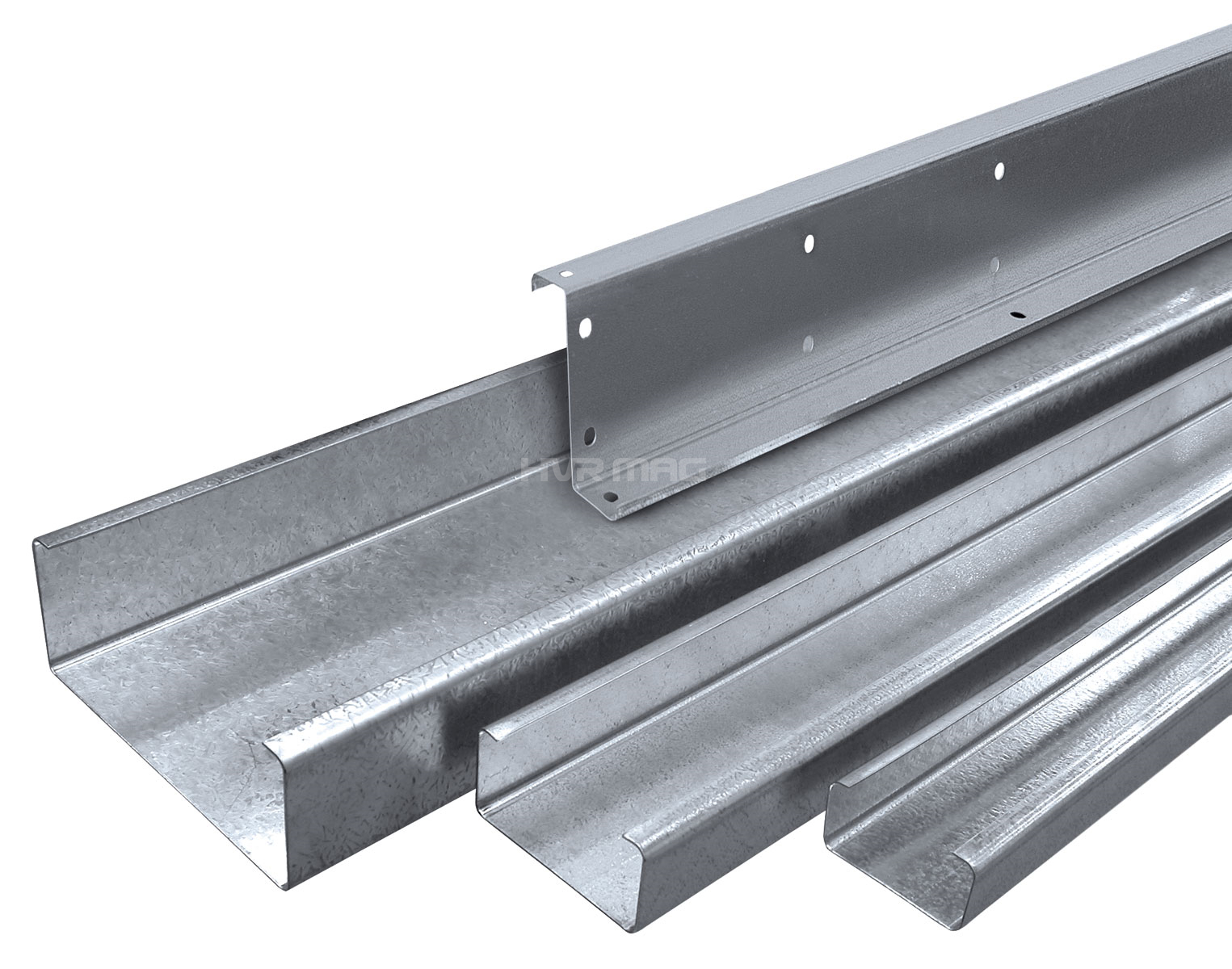

What are C purlins?

C purlins, also called steel channels, are designed to form the walls and floor joists of a building shell structure, making them also ideal for supporting beams needed for flooring. In addition, C purlins can also be used for door framing, roof trimming, window trimming, parapet rails and side rails.

3 ways that C purlins are often used

C purlins have many uses, primarily structural, and here are a few common examples:

#walls

C purlins are often used to build walls for garages, warehouses, and other metal buildings. C purlins can support a much more significant amount of weight, and they are much more rigid.

#roofs

On light-duty roofs, C purlins can be used as rafters, running from the roof's eaves to the ridge, where they provide support for the roof deck.

#vehicle frames

C purlins are often used to construct the frames of vehicles and are often specially formed for that particular function. Heavy-duty C purlins are typically used to create the mainframe rails, running from the front of the car to the back.

The difficulty in handling C purlins

As you can see, the C purlins have an angle of 90 degrees. Compared to the steel plates, they require more effort and skills to pick and place. And also, C purlins need a lot of room to place, so the handling tools can’t occupy most of the workplace.

Why are magnetic grippers considered reliable handling tools?

- decreased labour cost and increased safety

Automated systems remove workers from the workplace, thus safeguarding them against the hazards of the factory environment. And also, if the robots lose power or have to make an e-stop while performing a task, electro-permanent magnetic grippers ensure that there is no risk of dropping the part being handled. It also reduces the worktime of operators.

-boost production

Magnetic grippers can deal with different sizes and shaped workpieces. It doesn’t require different designs for holding various sizes of material. Besides, an automatic magnetic gripper can work at a constant speed without pausing for breaks.

-attract more customers

With magnetic grippers, various products can be offered to meet customers’ needs.

Work directly with our experienced team to solve your toughest engineering challenges