There are numerous grippers on the market. Determining which is the best type to use is an essential issue that robotics users must face.

What is a gripper?

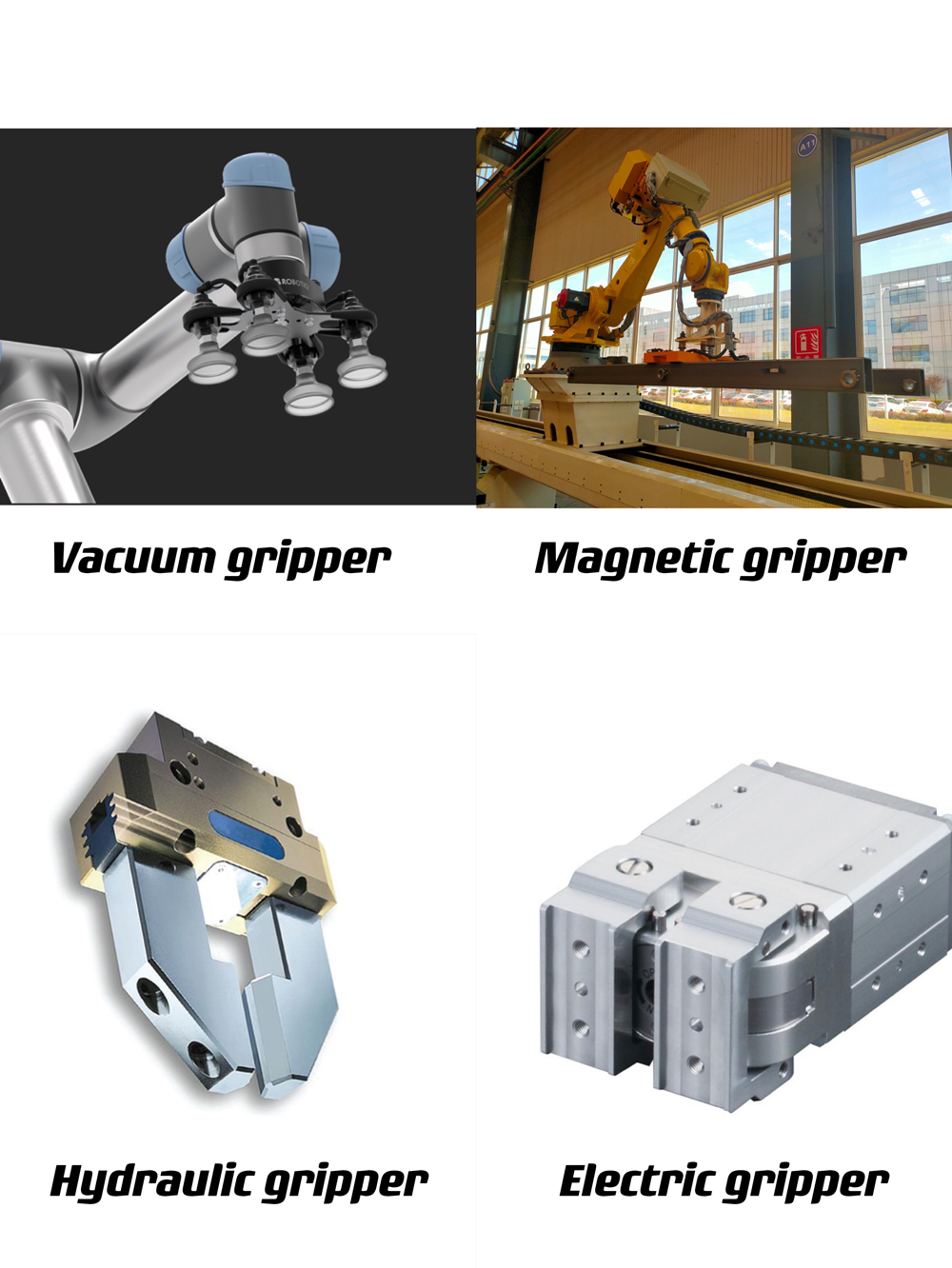

Grippers are devices that allow robots to lift and move objects. They includes magnetic grippers, vacuum grippers and so on. When combined with a robot arm, grippers enable manufacturers to automate critical processes, such as assembly, pick and place.

There are various different types of grippers available. It may be difficult for us to know which robot gripper types are best suited to which applications with so many choices.Today, we will talk about the most popular grippers in manufacturing and explore the pros and cons of different grippers.

Types of grippers

Choosing the right gripper seems challenging, especially with so many different types of grippers in robotics. Generally, grippers can be divided into 5 main types.

Vacuum grippers

Vacuum grippers use a rubber or suction cup to generate atmospheric pressure and a vacuum to pick up objects. The vacuum flow must remain uninterrupted to ensure that your robot can safely hold the thing.

You will find vacuum grippers being used in various applications, but one of the most popular applications of vacuum grippers is packaging and palletizing.

Vacuum grippers can handle different types of items and have a lower price compared to other grippers. But it’s sensitive to dusty conditions. Vacuum grippers are not ideal for all situations.

Pneumatic grippers

Pneumatic grippers use compressed air to operate gripper jaws or fingers. These fingers are similar to human fingers, helping in grasping, holding and releasing the workpieces. They are primarily used in automated manufacturing processes to grip the parts. The parts can range from small objects to large workpieces.

It has a low cost and large grip force, and it also can operate in tight spaces and has fast response times. However, Pneumatic grippers are best applied to handle single part types. So they are not so suitable if your factory produces plenty of mixed items. Also, Pneumatic grippers provide limited force and position control and require compressed air to function.

Hydraulic grippers

Hydraulic grippers are designed for a hydraulic system. Hydraulic grippers are powered by hydraulic fluids, offer more gripping power than pneumatic grippers and make themselves ideal for heavy-duty applications.

On the one hand, Hydraulic grippers are used when there is a need for extra gripping force. On the other hand, Hydraulic grippers are more costly, and they are generally less accurate than pneumatic or electric. They tend to be higher maintenance than other grippers.

Electric grippers

Electric grippers are the other option when looking for a power source for robotic grippers. Electric grippers are popular for many applications, including pick and place. They are suitable for high speeds and light or moderate force applications. Because it’s easy to control, electric grippers appear increasingly in industrial uses. A microprocessor can be added to a force sensor which can be made to handle different part types and vary gripping force and speed. But they tend to be more expensive.

Magnetic grippers use a magnetized surface to grab the metal items. Magnetic grippers are most common in industries where sheet metal and automotive parts are moved along an assembly line.

HVR offers you the most competitive electro permanent magnetic grippers. The technology of the magnetic grippers uses electrical power only for a few seconds of inactivation and deactivation. The workpiece will not fall down due to the power outage. They have a fast grasping speed and only require minimal maintenance, making them a flexible and cost-effective choice for manufacturers. There is a trend to use electro permanent magnetic grippers.

How to choose the right robotic gripper?

There are several items to keep in mind when choosing a gripper. There are some essential questions to ask when selecting a gripper for your robot:

-Will the gripper be handing a single item or a mix?

-What types of things will be handled?

-What shape/size are the things?

-Will the gripper need to operate in tight spaces?

HVR is an electro-permanent magnetic grippers manufacturer. We cannot only help you choose the right gripper, but we also customize the gripper to fit your specific product needs. Choosing the proper grippers is essential to ensuring successful automation applications.

Work directly with our experienced team to solve your toughest engineering challenges