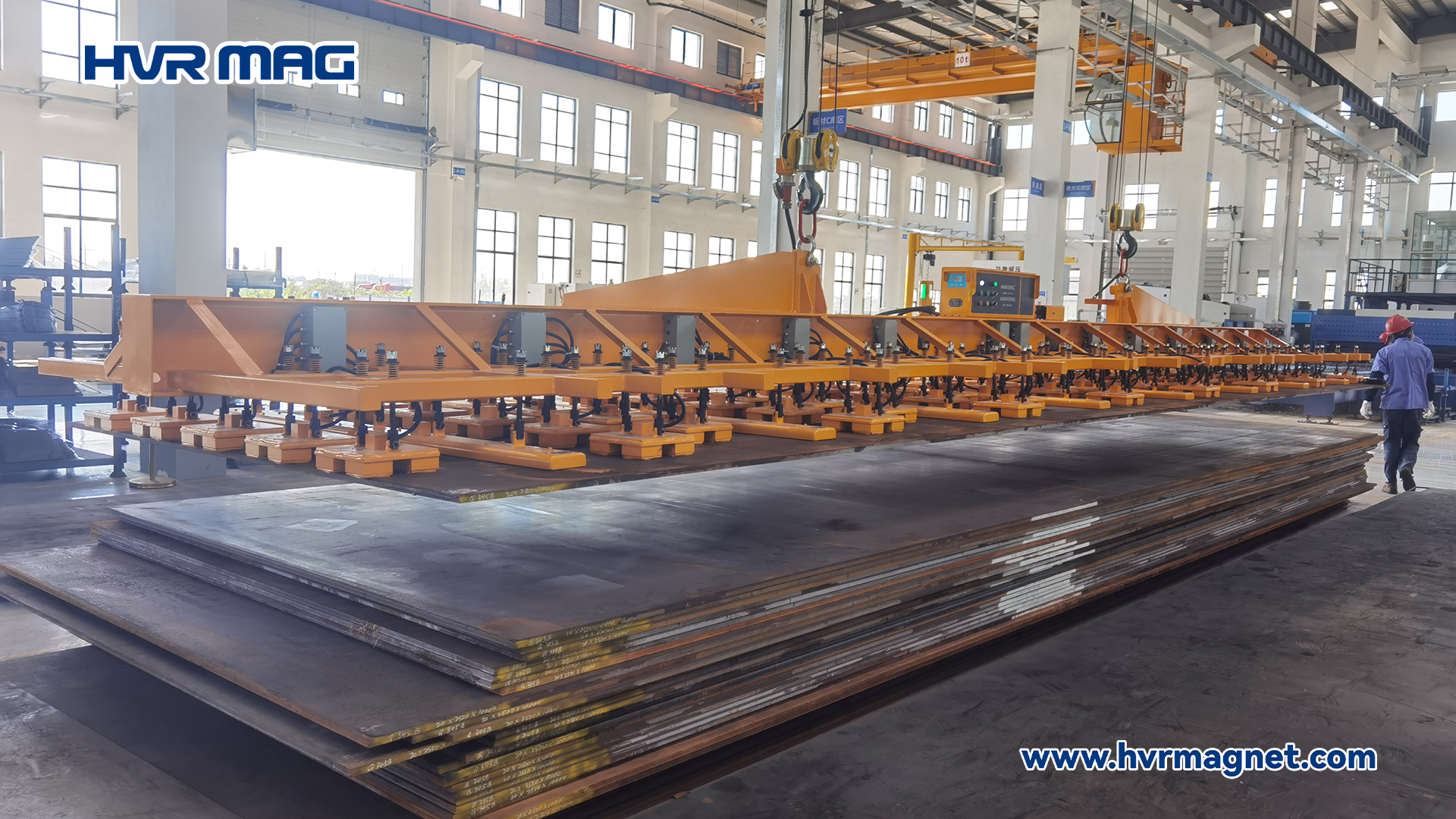

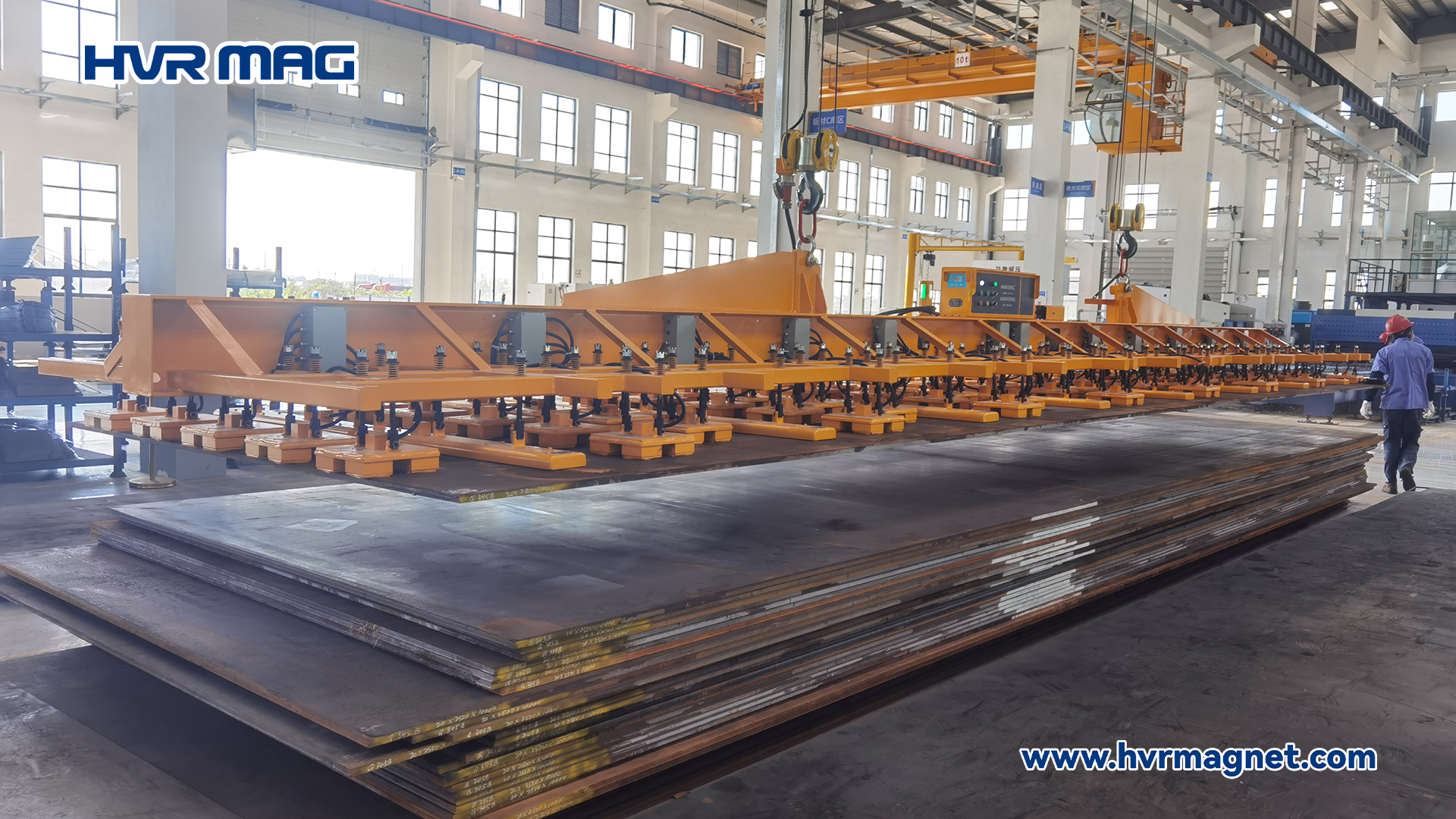

In industrial settings, efficiently loading steel plates onto cutting machines is critical for maintaining production flow and ensuring high-quality cuts. Various lifting devices are available for this purpose, including hooks, plate clamps, permanent magnets, electromagnetic lifters, and electro-permanent magnets. This article explores the strengths and wea

Read more »