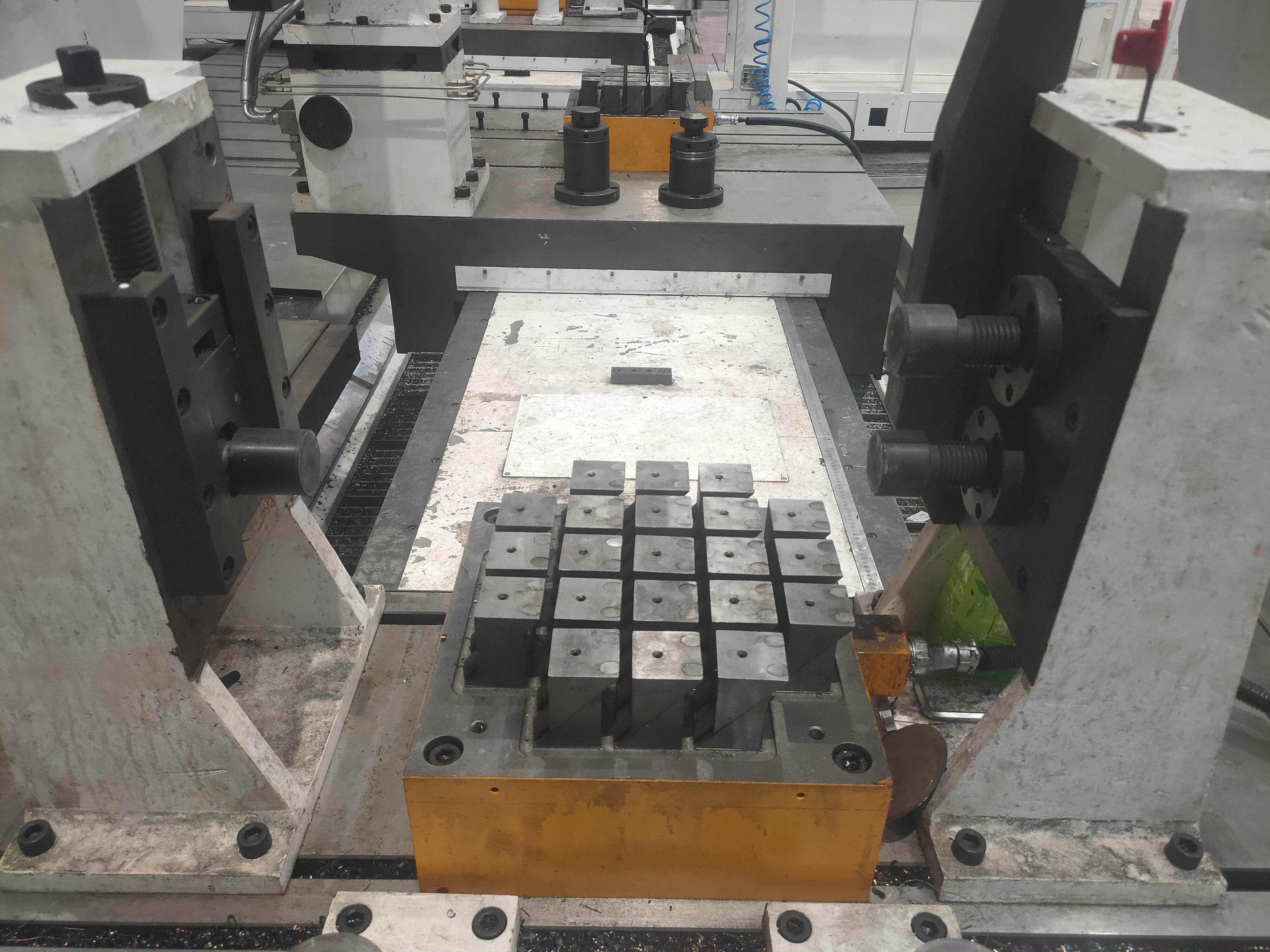

The cases illustrate the use of magnetic chuck in the boring of excavator rocker arms.

The customer previously used an ordinary horizontal milling machine with vises and platen to process.

1 Manual clamping, slow positioning, high labor intensity, and low efficiency

2 The machine tool is unstable due to defects such as height difference formed by welding deformation of the workpiece

3 Inevitably, the workpiece surface will be scratched when the workpiece is clamped in the vise and platen, and the clamping force will cause deformation of the workpiece.

HVR gave him a suitable solution to solve these problems:

The feedback from our customer:

1. effectively overcome the processing vibration generated by the original process, making the production process more stable and reducing the product defect rate.

2. Significantly improves production efficiency. Instead of boring 1 hole at a time, 3 holes can be bored simultaneously, increasing production capacity by more than 3 times compared to the original process.

3. Significant reduction in product failure rate.

4. Reduced labor costs; 1 person can simultaneously look after 3 milling machines.

Never hesitate to find a suitable tool to improve your efficiency! Contact HVR now for more information!

Work directly with our experienced team to solve your toughest engineering challenges