This article mainly discusses Schunk magnetic gripper and magnet gripper from HVR MAG and their features respectively in industrial automation.

Robot with Magnetic Gripper How Does It Work?

Magnetic grippers mounted on robot, use a magnetized surface to grab metal items. This type of gripper doesn’t usually incorporate fingers or jaws, instead relying on smooth magnetic surfaces for handling. With magnet gripper, robots can handle a variety of material sizes, grasp quickly, and allow easy grasping of a wide range of product shapes including items with holes, like handling perforated steel plates.

There are many possible applications for robots in the manufacturing process, with the most frequent uses being found in machine tending, welding assembly, packaging and palletizing applications.

Schunk Magnetic Gripper

Schunk provides robot grippers ranging from finger grippers to magnet grippers.

It supplies 2 types of electrically actuated magnetic gripper: EGM and EGH.

EGM: up to 118 kg workpiece weight, playload: 9-296kg

EGH: 3:1 ratio of workpiece weight to dead weight

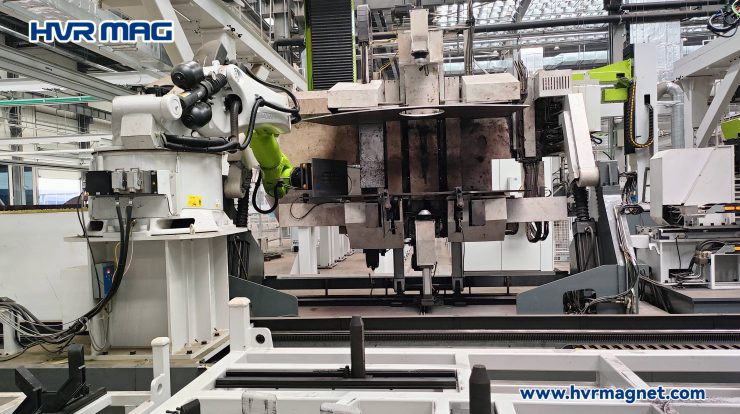

Magnet Gripper from HVR MAG

As a professional electro-permanent magnet manufacturer, HVR MAG accepts customization requests from clients for magnet grippers in various industrial application.

Electrically switched magnetic gripper, size/shape/gripping force can all be tailor made to get the most of your steel material handling efficiency. That is to say, HVR MAG can provide gripping magnet for both small and large workpiece, with a maximum gripping force ranging from 3kg to 720kg.

Features of magnet grippers from HVR MAG:

1.Lightweight to maximize end-of-arm capacity.

2. Customized gripper design to get the most of steel material handling efficiency.

3. Offers one surface to grab an object – avoids the issue of having robotic fingers that are too large or uniform to handle small and/or irregularly shaped pieces.

4. Suitable for holding steel parts with holes or unusual grooves.

5. Fast grasping speed – easy grasping and dislodging

6. No energy consumption in gripping state.

7. Remain holding of load even in scenarios with emergency stop.

8.Requires minimal maintenance – a flexible and cost-effective choice for manufacturers

Electro-permanent magnetic gripper for energy-efficient handling of ferromagnetic workpieces in automation. If you have any questions about robot magnetic gripper, reach out to HVR MAG experts for assistance.