Robot arm gripper has been widely used in recent years because it is so easy and quick to use. Robotic arm gripper can be used in the engineering process to hold the machined object in the correct position. It can also be used to check the size or quality of the workpiece. Or it can be used to perform simple gripping and release movements. Nowadays, there are also welding manipulators. For most operations in production, robotic arm grippers can now be used instead of manual labour. Faster, easier and safer.

Robotic arms are strong arms in automated production, the point of force. Robot arm gripper actually acts as a human hand. Imagine a scenario where a person is carrying an object in their hand. If it is square and has no handle, you would choose to hug it up. If the object is like a bag or bucket with hooks, the person would choose to grab the hooks with their fingers and carry it. The robotic arm gripper is designed to mimic this range of human behaviour. This is the main reason for developing the robotic arm gripper: by taking on the weight that would otherwise be carried by a human. The benefits are not only in terms of time and effort saved, but also in terms of worker safety.

Types of robot arm gripper

Robot arm gripper are designed according to the shape, material and size of the workpiece to be gripped. There are three general types: mechanical, vacuum and magnetic. The mechanical type uses mechanical fingers to grip the workpiece. Vacuum cups, on the other hand, are used to attract workpieces through the “palm of the hand”. It is suitable for smooth, flat materials such as glass. The magnetic type is also a attract method, but is limited to magnetically conductive materials.

Although the robotic arm gripper is not as flexible as a human finger, it can still help you save a lot of labour and money. For example, HVR MAG’s magnetic robot arm gripper requires only a small magnet to pick up relatively large steel parts. This is because the magnetic gripper, made of electro-permanent magnets, has a magnetic suction force of up to16 kg/cm².

Usages of magnetic gripper

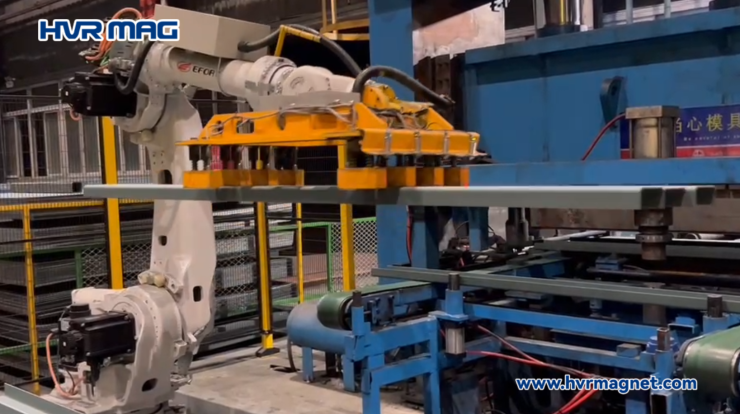

Magnetic robot arm grippers are most commonly used as assembly grippers to replace manual handling, sorting and palletising of cut steel parts. If the workpiece size is small, we can design it as a multi-magnet linkage gripper so that several parts can be gripped at once. This improves assembly efficiency. When handling heavy and large steel parts, the use of a magnetic robot arm gripper can reduce the labour intensity of workers and save a lot of time.

HVR MAG, as a professional manufacturer of electro-permanent magnetic grippers, can offer you efficient robot arm gripper solutions. Feel free to contact us at: export@hvrmagnet.com