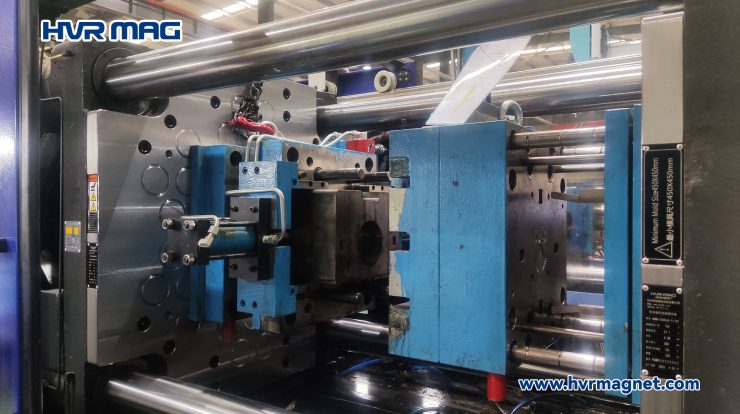

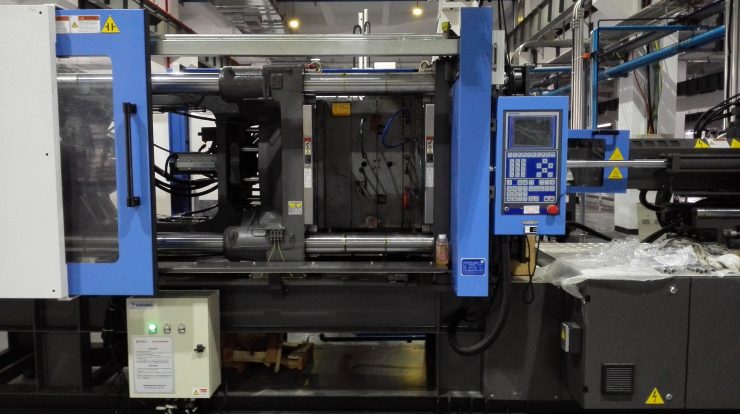

The story of magnetic platens and Haitian injection molding machines happens in the mold changing process in plastic production lines. Let’s see some applications of magnetic mold clamping plates on different Haitian IMMs in different plastic manufacturing factories.

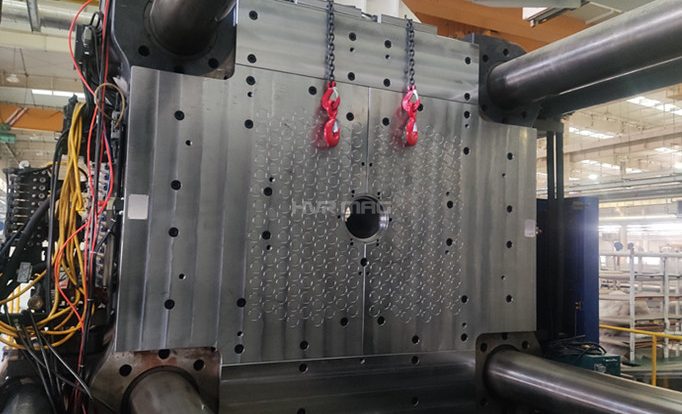

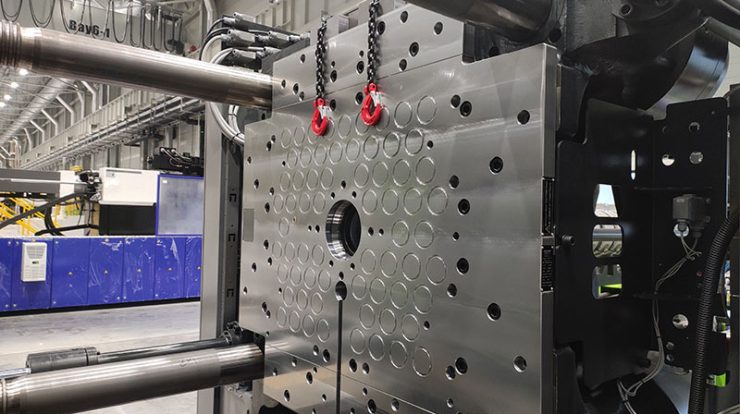

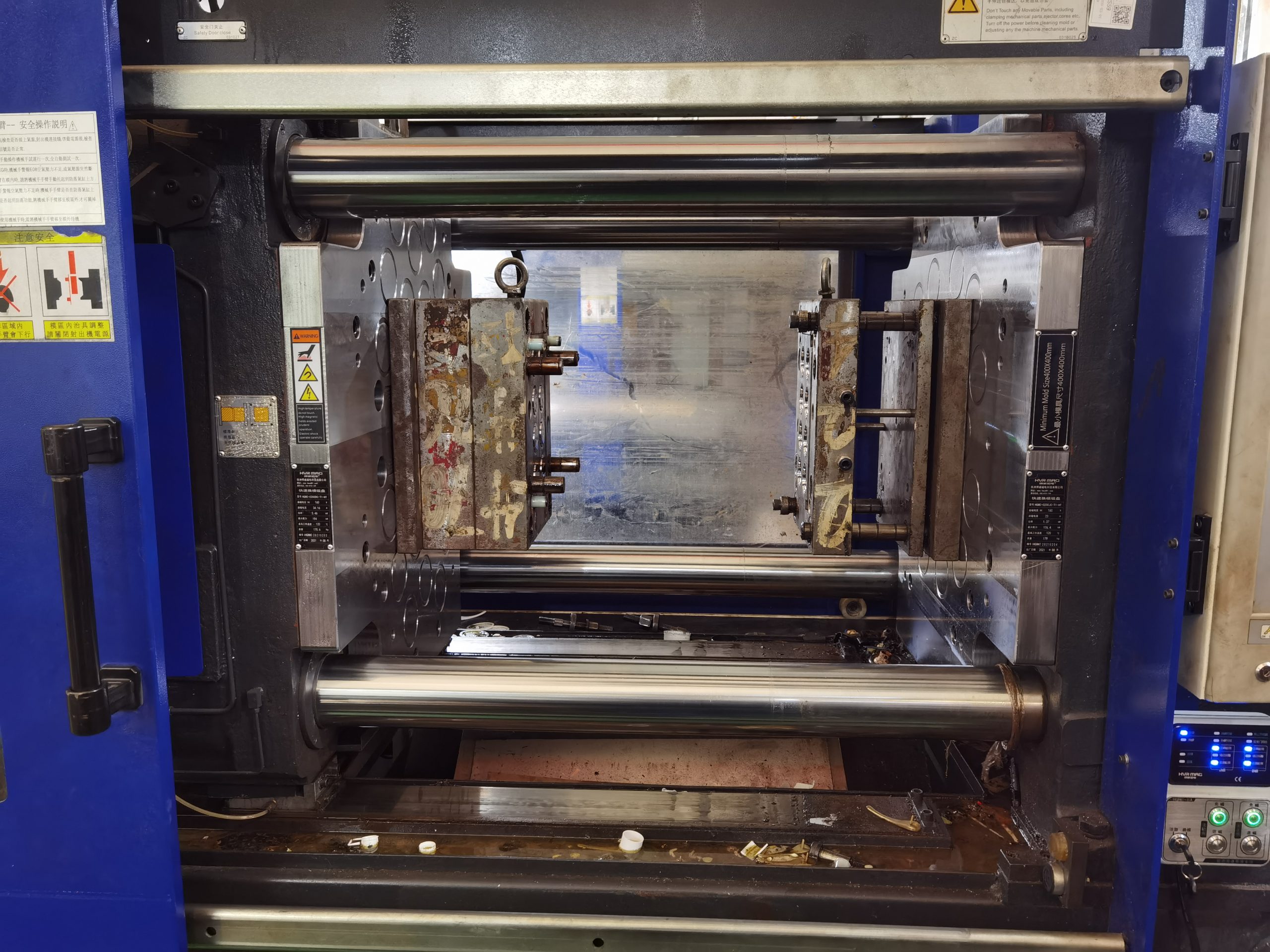

Our quick mold change system includes: 1 fixed mold clamping plate, 1 movable platen, human-interface panel, control cabinet. They’re magnetized to clamp the mold, and demagnetized to release the mold.

Load the mold → Push the button → Run the Machine

Quick mold change done within 3 minutes!

Then, what is quick mold change?

It means that the mold can be changed within the shortest time, which counts from the time spent on releasing & unloading the mold and loading & clamping a new one. The injection material for the next part is in place, automation is set-up and the new mold is located and clamped in the same position, the same way, every time.

When the magnetic platen system is activated, a short burst of electric current temporarily changes the polarity of the magnet so that the magnetic field enters into the mold for clamping or is disengaged from it for unclamping.

This magnetic clamping system is suitable for plastic injection molding machine and metal stamping press, making operations safer and more efficient.

Why Are Magnetic Platens Used for Plastic Production?

Production lines are often required to make a relatively small quantity of parts in a short time so the order can be delivered quickly. Doing this easily and safely — while being able to compete in the global market — requires a quick mold change system.

Using a quick mold change system, injection molding operations become safer and more efficient. Heavy tools are swiftly moved into position and are located securely and repeatably with quick change mold clamps. Faster changeover means less downtime, more capacity and increased operational flexibility. Productivity rises, and that means a healthier bottom line.

Magnetic Platens Manufacturer

HVR MAG can design and manufacture magnetic mold clamp plates for 50-4000T plastic injection molding machines.

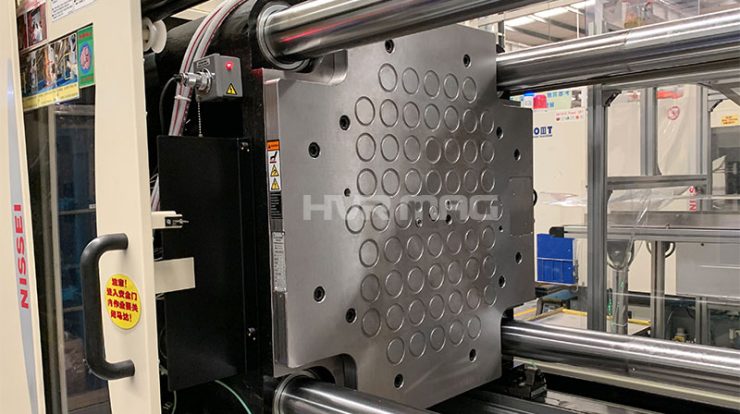

In addition to Haitian, our quick mold change solution has served IMMs of various brands, including Arburg, NISSEI, YIZUMI, ENGEL, TOSHIBA, LK, Tedric, Husky, Haitian, etc.

As to the mold, we have projected clamping system for two-plate mould and three-plate mould, single-cavity or multi-cavity, whatever the types and sizes of the mold. For more applications, please go to our website www.hvrmagnet.com. Or get in touch with us now for query or customization.