What is Quick Mold Change System

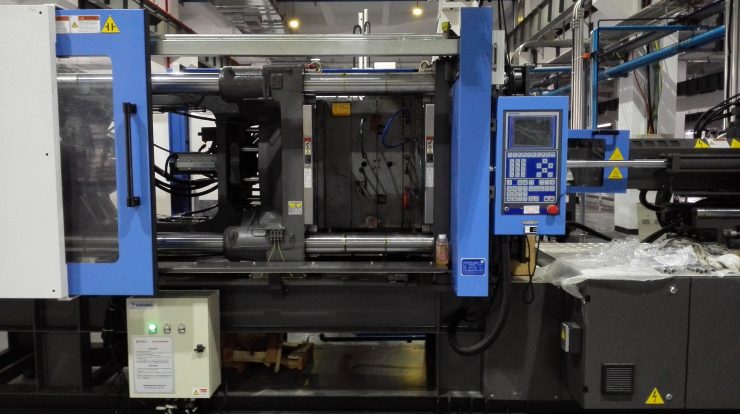

Quick mold change system utilizes optimized unique electro permanent magnetic clamping technology, to clamp molds and dies for plastic injection molding machines and metal stamping press machines. Mold Change, 3 Minutes Done.In this way, the changeover time of molds and dies is immensely reduced by up to 95%. For plastic injection molding machines, the larger the tonnage is, the harder and longer the mold changing process is. But with this technology, everything is different.

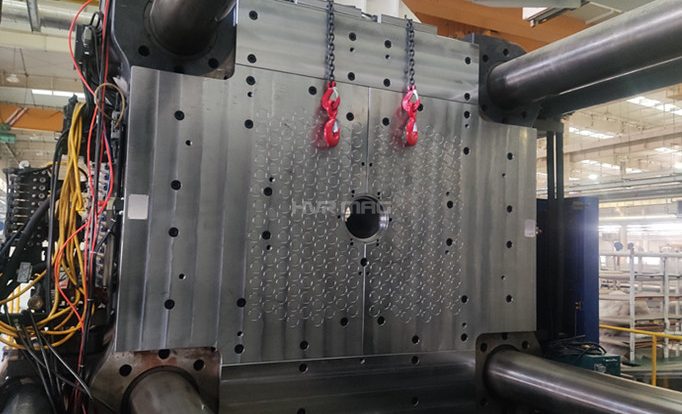

Actual Cases for 3300 Ton Haitian IMM

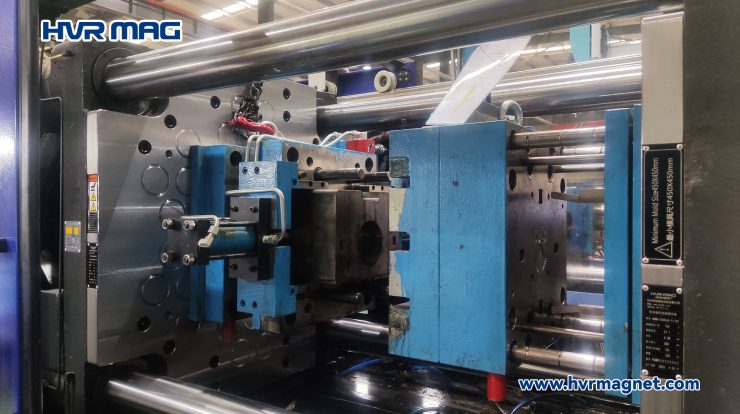

Check the new installation of quick mold change system, supplied by HVR MAG, on a 3300 ton Haitian injection molding machine, to reduce the changing time of molds, in a bus manufacturing company.

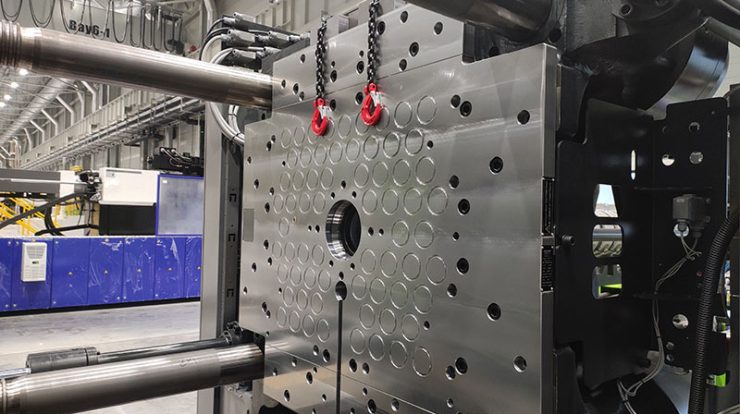

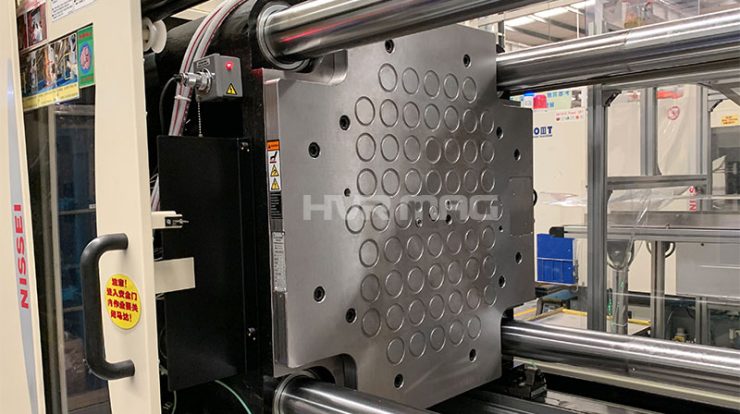

First of all, let’s get acquainted with the components of our mold clamping system: 1 movable magnetic mold clamping platen, 1 stationary magnetic mold clamping platen, human-machine interface panel, and the power control cabinet.

As we can see from the pictures took onsite, the edge of the mold baseplate has reached the margin of the baseplate of machine. If the molder goes with the hydraulic mold clamps, there won’t be enough space for their installation. Besides, there’s always a risk of oil leakage with hydraulic clamping system.

But with our magnetic quick mold change system installed, all these concerns are addressed, with extra benefits:

- Uniform magnetic clamping force on the mold, less risk of mold distortion caused by mechanical clamping

- Besides, our magnetic quick mold change systems sets no restriction the mold size

- Mold changing time could be significantly shortened

- Requires only one operator to monitor/control the mold changing process and injection molding process.

In conclusion, HVR MAG Magnetic Clamping System is suitable for 50-4000ton injection molding machines to allow for quick mold changeover, resulting in shorter downtime of injection molding machines without any changes to the molds. It provides a uniform mold clamping force act on whole contact surface that allows obtaining good quality parts even with the first mold, drastically reduces mold changeover time (up to 90%) compared to a conventional procedure. For more further technical information or other queries about our quick mold change system, please contact us for customization and quotation.