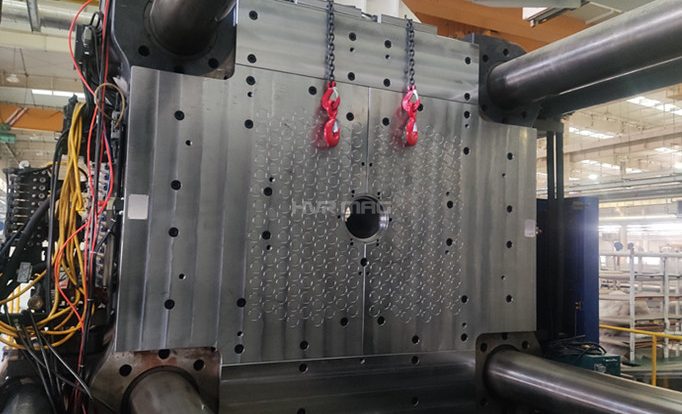

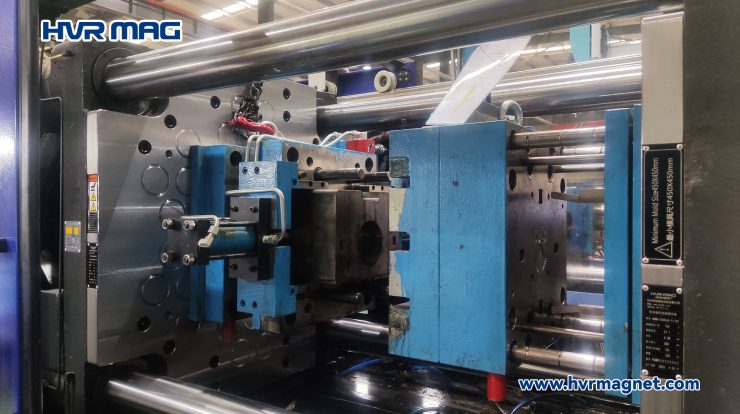

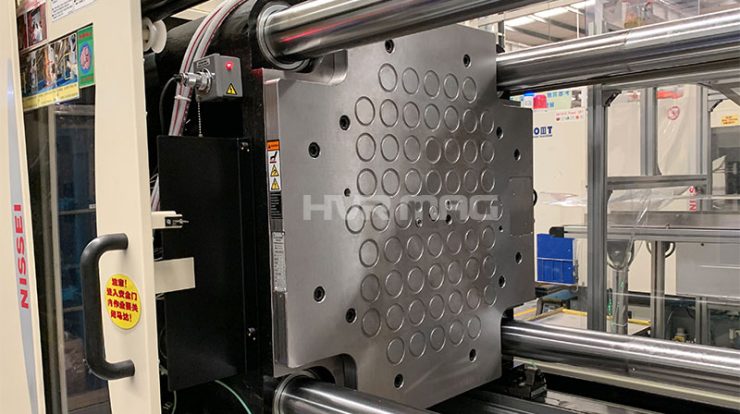

The Quick Mold Change System is an auxiliary device that is added to plastic injection moulding machine or press machine to make the process of changing moulds efficient, simple and fast. Conventional mould clamping methods such as mechanical clamps result in very tedious and lengthy mould changes, with approximately 40% of production time being wasted on mould changes. Furthermore, mechanical clamps do not guarantee a completely uniform clamping force, which affects the consistency of the product quality.

HVR MAG offers a magnetic mold clamping system to solve this problem for manufacturers of plastic, silicone and rubber products. Many people are concerned about the safety of magnetic plates, so we would like to introduce you to the main safety features of our quick mold change system.

Safety feature 1: Restrictions on changeover requests

To prevent misuse of the mould change system, the following conditions must be met before magnetisation and demagnetisation can take place.

- The mould change key switch is in the mould change state.

- The safety door of the injection moulding machine is closed.

- The injection moulding machine is in the high pressure state with the mould closed and locked.

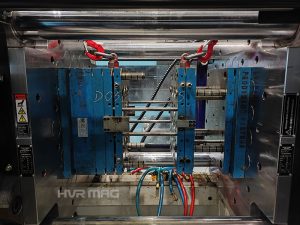

- The mould is held in place by magnetic plates on both sides

- The temperature of the moving and fixed side does not exceed the temperature protection threshold of the magnetic template.

When the above 5 conditions are met, the mould change is allowed and the charging and demagnetising system responds. The above 5 conditions are displayed on the touch screen and can be directly observed.

Safety feature 2: Interlock protection signal

The interlock protection signal is output by the quick mould change controller. After the system has successfully clamped the mould, if an abnormality is detected in the clamping system during the injection moulding process, the interlock protection signal is output to stop the operation of the injection moulding machine in an emergency. The status of the interlock protection signal is determined by the following conditions:

- The magnetization of the movable orfixed plate failed, the magnetic flux detection and suction detection did not pass.

- The movable orfixed side mould have fallen off or been pulled apart during the injection process.

- The temperature of the movable orfixed side mould exceeds the temperature protection threshold of the magnetic template during the injection process.

- The magnetic flux of the movable or fixed side mould is reduced due to misalignment during the injection process.

If the above fault occurs after the mould change key has been turned to the injection state, the touch screen will indicate that a fault has occurred and the fault information can be viewed in detail on the fault alarm page.

If you would like to know more about our quick mold change system, please contact us at:export@hvrmagnet.com