Learn what robotic machine tending is, how it works, and the features of magnetic grippers on industrial robots to load/unload steel parts in automation.

What Is Machine Tending?

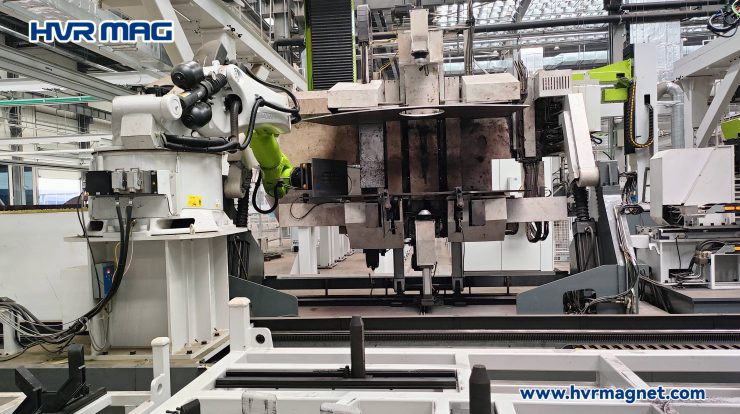

Machine tending refers to the automated operation of industrial machine tools in a manufacturing plant, primarily using robot automation systems. To put it simply, it means to load and/or unload a given machine with parts or material.

What Is Machine Tending Robot?

Machine tending robot is used to secure the product from a supply position, transport it to a machine, interact with the machine and then remove the finished part from the machine.

Managing this process by robot minimizes incorrect product placement due to human error and increases speed and efficiency of production. A robotic machine-tending process can be repeated endlessly, assuming the robot continually receives raw parts and the machine produces quality parts.

How Robotic Machine Tending Works?

Robotic machine tending can provide manipulation and transport capabilities that are more complex than basic material handling processes. Machine tending robots are used to secure the product from a supply position, transport it to a machine, interact with the machine and then remove the finished part from the machine. Managing this process by robot minimizes incorrect product placement due to human error and increases speed and efficiency of production.

Magnetic Gripper Features

•Compact, heavy-duty aluminum housing.

•For loading/unloading various ferromagnetic workpieces, employs a strong permanent electromagnet and can instantly clamp/grip the magnetic substance.

•Energization only when magnetizing/demagnetizing.

•Keep magnetizing even in power outage.

•Can magnetize and carry various size of the substances by incorporating an industrial robot.

•Minimum residual holding force when the workpiece is released.

•Safety feature: the magnet settings “grip” and “release” are maintained in event of power loss. No electric power required.

•Ideal for handling unusually shaped steel parts, like metal blanks, punched steel parts, or perforated metal sheets, in press-tending and bending applications

•Can also be used for destacking and separating sheets or palletizing metal parts.

•Used on robot arm or automation line, like a pick and place machine to hold or move.

•Customization to match challenging application requirements.

Benefits of machine tending with robot gripper include:

Maximize throughput with higher speeds and performance

Increase system uptime

Reduce operation costs

Increase quality

Repeatable accuracy and improved quality of production

Minimizes human error & improves ergonomic conditions

Short ROI & lower overhead cost compared to manual machine tending

Increased machine and system utilization & capable of 24/7 machine tending

Machine tending can be dangerous work and requires the consistency that a robotic solution can provide. With tailor made magnetic gripper, robotic machine tending replaces human interaction to move product from a supply position, transport it to a machine, orient it, and then interact with the machine, in a safer and more efficient way. At HVR MAG, you will find automation magnets for the automated picking up or gripping of ferrous workpiece suitable for all shapes and sizes.