Robotic grippers are end effectors attached to industrial robots. They are an integral part of industrial automation. Today, robots can be used to replace manual labour in many production processes. Accordingly, there are different types of robotic grippers. Each has its own advantages and disadvantages.

Mechanical: Mechanical robotic grippers can handle all kinds of materials. However, when used for gripping larger workpieces, they are often complex in design. They can also be inflexible due to their size and weight.

Vacuum type: Very simple and inexpensive. Can grip many materials. But it can only grip smooth, non-porous, flat surfaces. And the suction cup’s rubber ring wears easily and needs frequent maintenance and replacement.

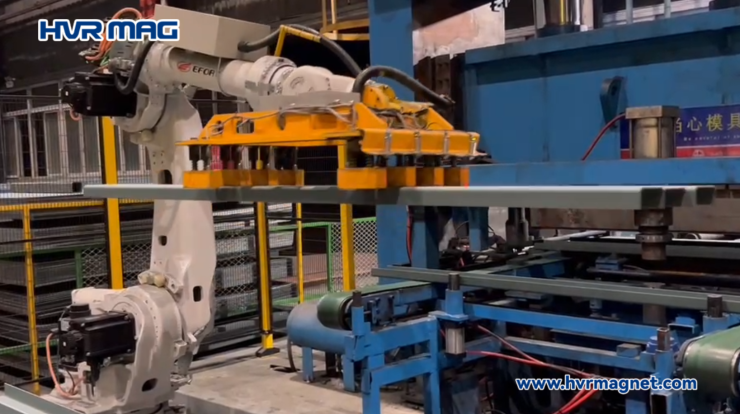

Magnetic: There are also several types of magnetic robotic grippers: electromagnetic, permanent magnetic and electro-permanent magnetic. Their common features are as follows.

Advantages:

- Only one contact surface with the workpiece is required for gripping.

- Simple and fast gripping process.

- Flexible, no need for multiple structural components.

- Possible to grip workpieces with holes.

- Very low maintenance costs.

Disadvantages:

- Workpieces can be thrown off if moved too fast.

- Magnetic force is reduced even if there is a small amount of oil on the surface of the workpiece or magnet.

- Machining debris may stick to the magnet when the workpiece is removed.

- Workpieces handled may have residual magnetism.

- For handling ferrous magnetic materials only.

The three types of magnetic robot grippers differ in the way they operate:

Electromagnetic gripper: The large depth of magnetic permeability allows several steel pieces to be picked up at the same time. The electromagnet is energised by an internal copper coil to create a magnetic field. The disadvantage is that once the electromagnetic field is broken, it disappears and the workpiece falls off. Also, when gripping thin steel, the steel may tends to stick.

Permanent magnet gripper: Very energy efficient as no electricity is required. It is also safer because the magnetic force does not require electricity to maintain. However, the amount of magnetic force cannot be precisely controlled. Sometimes it may be necessary to manually release the workpiece from the magnet.

Electropermanent magnetic gripper: The magnetic field of the electropermanent magnet is generated by the internal permanent magnet material. It uses electric current as a magnetic switch. As a result, it does not consume much electric power and does not lose its magnetism when the power is turned off. It can also be designed with a demagnetisation function. It is safe, energy efficient and easy to use.

These are the advantages and disadvantages of the various types of robotic grippers. HVR MAG can customise your robotic grippers with electro-permanent magnet. If you need more information, please contact us at:export@hvrmagnet.com