Speaking of robot gripper, we usually think of mechanical type and vacuum grippers. But what kind of robot gripper is suitable for steel materials? Without a doubt, it is the magnetic gripper.

Robot gripper suit for steel materials need to have the following characteristics:

- The ability to handle heavier items. Steel workpieces are relatively heavy, especially medium or large workpieces.

- Resistance to wear and tear. The surface of steel is usually not particularly smooth and flat, so the contact surface of the gripperneeds to be resistant to wear and tear.

- Does not leave scratches. When working with thin steel sheet material, it is important that no scratches are left behind, as this will affect the final result of the product.

- Does not interfere with processing. Steel materials often needs to be cut or welded. In this case the gripperneed to be as small as possible so that it does not obscure the processing range of the steel.

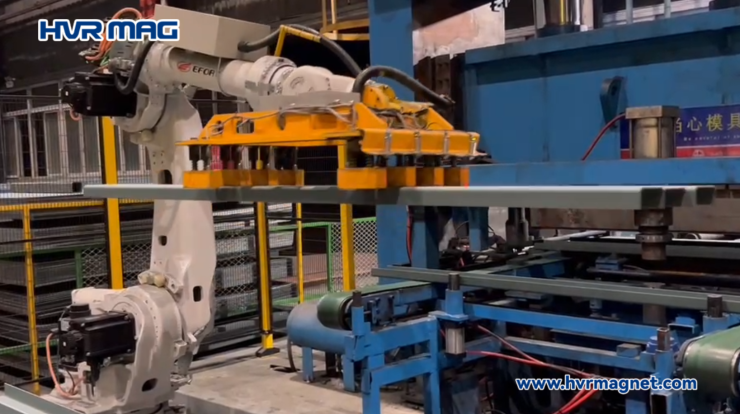

The magnetic robot gripper from HVR MAG perfectly matches the above-mentioned conditions and is suitable for the handling of all types of steel.

It has the following characteristics:

- Powerful magnetic strength. The HVR MAG robot gripper is made of electro-permanent magnets and can reach a pull force of up to 16 kg per square centimetre. The magnetic strength of the magnets can be customised. It can be used to its full potential as long as there is sufficient contact area with the steel.

- Flexibility. The size of the magnetic robot gripper can be customised, but is usually much smaller than the steel itself. If you need the robot to grip the steel and then rotate, it can flexibly follow the robot’s movements. The strong magnetic suction keeps the workpiece stable during the turning process.

- Maintenance-free, the HVR robot gripper has a fully rigid surface that is water and oil resistant and resistant to wear and tear. When gripping workpieces, the contact surfaces of the magnets and the workpieces are parallel, so there is no serious friction even when gripping steel with rough surfaces. You only need to regularly check that the magnet contact surfaces are clean. No other maintenance costs are required.

- Versatile. Because the magnet only needs one contact surface with the workpiece, there is no obstruction around the workpiece. This means robot gripper can be used in a wide variety of working conditions. For example, when gripping a thin steel plate for processing on a bending machine, the adsorption point is in the centre of the plate. Therefore, all sides of the plate can be bent at will. It can also be used to hold the workpiece on a welding machine. As long as the distance between the welding point and the magnet is at least 5 cm, the weld will not be affected.

So the HVR robot gripper can do more than simply gripping. It can grip the steel that you need to process and help you to complete the palletizing afterwards. It can also help you to hold workpieces in place when bending, welding or drilling. If you want more information about HVR and our grippers, please contact us at:export@hvrmagnet.com