Traditionally, companies use ordinary manual welding jigs and press plates for welding processing, which requires joint operation by multiple people. But the manual production efficiency is far less than ideal. With the popularity of automated production, people’s requirements for capacity production have been rising, and many companies have started to use welding magnets for robotic welding automation to improve production efficiency.

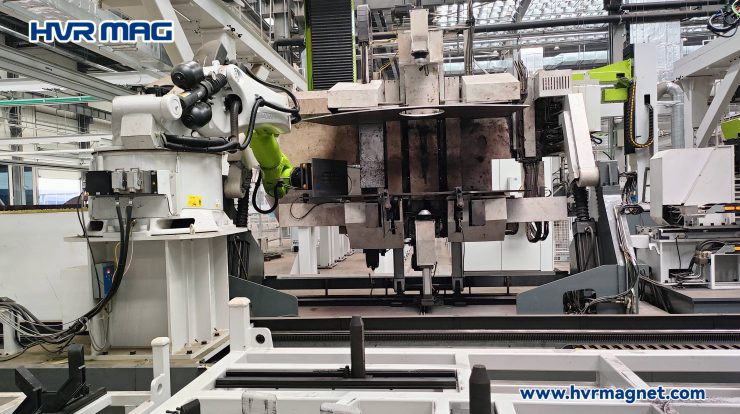

An automation integrator had transformed a welding line project, which originally used manual welding fixtures and press plates for processing, with every 5 people operating one set of fixtures. After the renovation by using welding magnets (electro-permanent magnets), the workpieces were fixed by the magnets automatically, with a PLC control system.

Compared to the original welding tooling, the electro-permanent magnet for the robotic welding system has the following advantages.

1. The clamping process is quicker and easier by using magnet welding fixtures. With a PLC system, magnets clamp the workpieces to the correct place, with higher efficiency.

2. Effective adaptation to different sizes or specifications of workpieces, with high stability.

3. The electro-permanent magnet welding positioners rely on strong magnetic force to adsorb the workpiece from the bottom surface, which can avoid surface pinching or deformation of the workpiece.

4. Electro permanent magnet doesn’t need electric current during the working process, so it’s energy-saving.

Customer feedback after using magnet welding fixtures

1. It can effectively overcome the deformation and pinching caused by the original production process, making the production process more stable and reducing the defective rate of products.

2. Significantly increased productivity, more than two times higher than before.

3. Significant reduction in workplace accidents

4. Labor cost reduction, from the original 5 people to operate a set of tooling to 1 person to watch 1 assembly line.

HVR MAG is a manufacturing vendor of electro-permanent magnets for 12 years. We have rich experience in designing and manufacturing magnets for robotic welding automation. The small-sized welding magnets, together with welding robots, can drastically improve production efficiency and make an intelligent factory. If you’re interested, please e-mail us at: export@hvrmagnet.com