Industrial robotics is regarded as a key technology to drive the up-coming Industry 4.0 evolution in various industrial manufactures, especially in metal industry. Magnetic grippers, as an important end-of-arm tool, has been seeing an accelerated growth of industrial robotics adoption.

Automation In The Metal Industry

The metal industry is one of the most versatile industries and therefore predestined for robot-based automation solutions. It requires perfection down to the smallest detail and top performance in difficult, sometimes extreme working conditions.

What Do Industrial Robots Do?

Typical applications of industrial robots include welding, painting, ironing, assembly, pick and place, palletizing, product inspection, and testing, all accomplished with high endurance, speed, and precision.

What do you use to handle workpiece for your automated metal working process?

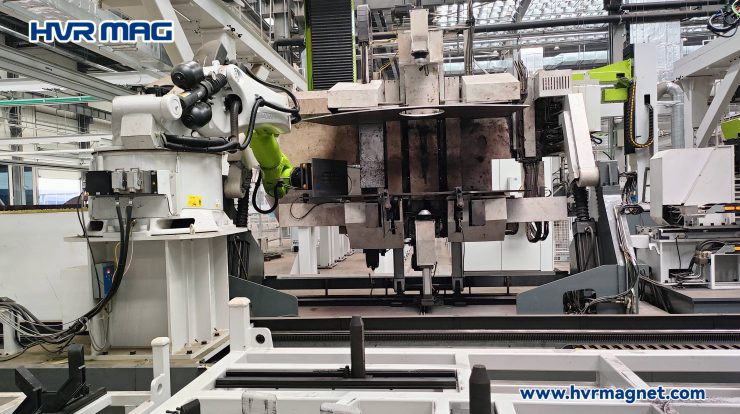

Magnetic grippers – the end effector that help industrial robots contribute in automated metal working process.

Robots are used in manufacturing to take on repetitive tasks, which streamlines the overall assembly workflow. The effective use of magnetic grippers is now prevalent in many types of automatic material handling applications, like pick and place of metal parts.

Increasing Efficiency, Reducing Time to Market

Automated handling of metal parts is perfectly tailored to the specific circumstances, which helps manufacturers to maximize the efficiency of the production system. While magnetic grippers for robots, make work considerably easier and accelerates the production sequence, for processing metal parts, from machining to loading and unloading machine tools.

Common Applications of Magnetic Grippers on Industrial Robots

◆Material handling

are utilized to move, pack and select products. They also can automate functions involved in the transferring of parts from one piece of equipment to another. Direct labor costs are reduced and much of the tedious and hazardous activities traditionally performed by human labor are eliminated.

Automatic material handling in welding line

◆Machine tending

Robotic automation for machine tending is the process of loading and unloading raw materials into machinery for processing and overseeing the machine while it does a job.

Metal stamping

◆Metal bending

◆Picking, packing and palletizing

Most products are handled multiple times prior to final shipping. Robotic picking and packaging increases speed and accuracy along with lowering production costs.

metal plate shearing

Picking for packing line

Type of Robots We Cooperated with

Cartesian Robot

Articulated Robot

Cylindrical Robot

The metal product manufacturing industry is a diverse space that already relies heavily on robotics and the right end effector to control costs, boost productivity and insulate workers from undue risks. In today’s challenging world market for metal products and structural components, metal product manufacturers continue to look for new ways to streamline their operations and allocate their human workers effectively, by taking up tasks that were previously performed manually.

HVR MAG offers customized gripping solutions for ferrous parts and workpiece in automated metal processing. Tailor-made magnetic grippers for robots, not only allow them to significantly increase production in less time and at less cost, but also to actually manufacture better quality products.