Magnetic Robot Grippers are widely used in the field of automation. Mainly including robot handling, sorting and palletizing, positioner fixing, welding clamping, group tooling and so on. Magnetic Robot Grippers of HVR MAG are made of electro permanent magnet(EPM). Which have following features.

Flexible

The EPM magnetic gripper is compact and can be mounted on all types of robots. Unlike vacuum grippers, they do not require the workpiece surface to be smooth. The magnetic gripper can be used as long as it has sufficient contact area with the workpiece and the air gap does not exceed 2 mm.

Energy saving

Magnetic robot grippers are often used for long periods of time. When electromagnet grippers are used, power consumption is very high. However, HVR’s magnetic grippers use EPM, which are very different from electromagnets. Electromagnets generate a magnetic field from a coil and require constant power to operate the magnet. While the magnetic field of an EPM comes from the permanent magnet material inside and the current is only used to act as a magnetic switch. And it only takes 2 seconds to energise and de-energize a grip.

Safety

Vacuum grippers are easy to leak and adsorption force is small, relatively speaking, the magnetic gripper adsorption is stronger and more stable. The coil of electromagnet is easy to become overheat during a long time work, which will affect the magnetic. The EPM has neither of these problems. It has a strong magnetic force of up to 16 kg per square centimetre. And it don’t need to be energised for long periods, so it does not easily overheat and lose its magnetism.

Customizable

HVR’s magnetic robot grippers can be customised to suit your application in terms of shape and size, magnetic strength, number of poles and contact surface shape. We have developed ultra-thin robotic magnetic grippers for truss robots, which are used to handle thin steel plates of comparable size. This ensures safety without causing wear to the surface of the steel plate.

Efficient

Our magnetic robot grippers have helped automate production in many factories, with significant efficiency gains. One customer, who manufactures oil pipes, relied on manual sorting of short round steel pipes before using magnetic grippers and robots. The array was 8 x 10 and manual sorting required several movements to complete. With our magnetic gripper it was possible to handle 80 short pipes (vertically) in one pass and the workpieces were neatly aligned after being placed in the packaging box.

Versatile

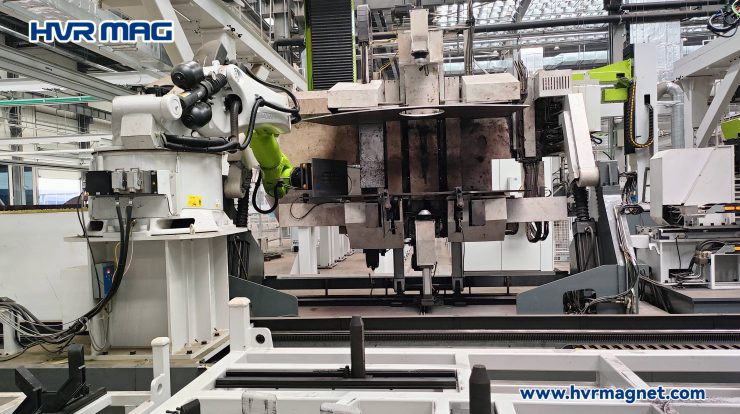

Not limited to handling, the magnetic robot grippers can also be used with welding robots. When working with welding machine, the magnet will not affected the processing as long as the distance between the magnet and the weld point is more than 50 MM. It can be used with other machines that need to hold workpieces for processing. We have many customised examples, such as magnetic grippers for angle steels on truss robots. Combined grippers with robotic arms for gripping steel plates on the bending machine: the magnets grip the workpiece and the vacuum cups reduce the vibration of the plates. For use in high temperature environments, our magnetic grippers have a conventional temperature resistance of 180°C. If your workpiece is processed at too high a temperature, a water cooling device can be added.

If your factory needs to move steel, fix processing, and then sort and palletise, magnetic robot grippers can do it all. The safe, energy-saving and efficient electro-permanent magnetic gripper is the best choice. For more information, don’t hesitate to contact us:export@hvrmagnet.com