What Are Steel Plates?

Steel plate, or structural steel is simply steel sheet material that can be customarily cut and welded to develop a more elaborate product. It is made by compressing multiple steel layers together into one; forming a plate of steel.

Types of Steel Plates

These include high-tensile strength steel plates, low temperature service type, atmospheric corrosion resistant type, abrasion resistant type, corrosion resistant type in various corrosive environments, stainless steel plates and clad steel plates with various cladding materials.

Steel plates can be manufactured by large steel factories or smaller, more specialized plants. They are are one of the many types of steel that can be produced, other types include steel bars, sheets, slabs, rolls, and more.

Usages in Industry

Steel plates are often used for structural and construction applications, pressure vessels, marine and offshore equipment, and military applications. The grade, elements and parameters of a steel plate are also important in how it is used.

How are they used in construction?

The largest consumer industries include shipbuilding, construction, machine building and large-diameter pipe manufacturing, among others.

- Construction of bridges and other structures

Steel plates are mainly used in this industry for the fabrication of steel structures:

I-beams, welded box-section columns and other support profiles that are made by cutting and welding elements from metal plates;

Building floorings and elements of the superstructure of bridges, trestles and galleries;

Medium- and large-diameter pipes that can be used both for utility lines (pipelines, chimney stacks, cabling, etc.) and as supports for structures and bridges.

- Machine building

Plates are widely used in machine building sectors:

To manufacture agricultural machinery components (ploughs, blades, harrows and parts of seeding machines);

To manufacture heavy underground and land machinery (casings, housings, high-stressed components for mining, road and handling machines, wear plates, crane jibs, etc.);

To manufacture components for cargo and passenger transport (load-carrying elements);

Machine tool engineering and heavy engineering (bodies and housings of wood and metal working machines, parts and components of equipment for metallurgical, chemical and other operations).

Steel plate is widely used to stabilize structures and protect mass units like bridges. Alternatively, it offers a foundation for constructing bigger materials and non-workable pieces. Steel Plate Systems are focused strongly on project details. This basically implies that some classes are more suited to different activities than others.

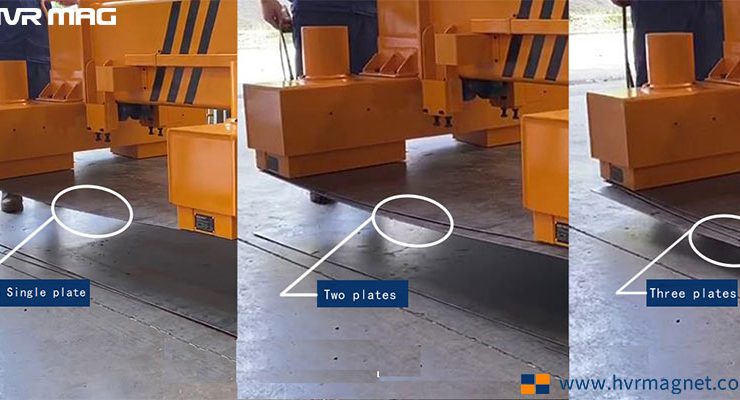

Lifting Equipment for Steel Plates

For either short or long, thin or thick plates, the lifting job has always been a tricky problem to steel mills or steel structures where plates need to be moved and handled every day. To help improve the handling efficiency and ensure the safety of personnel, HVR MAG offers made-to-order lifting equipment for steel plate – magnetic lifting beam. With our magnets for lifting steel plate, manufacturers no longer have to worry about the dropping of plate during the move, nor the low efficiency of moving them.

Visit www.hvrmagnet.com to learn more details and applications of our steel plate lifting equipment.