What Do You Call A Robotic Arm?

There are several synonyms, like robot arm, robotic arm, manipulator arm, mechanical arm, etc.

What Is The Difference Between “Robotic Arm” and “Robot Arm”?

Basically these two terms mean the same thing. They are used interchangeably in practice.

What Are the Pros and Cons of A Robotic Arm?

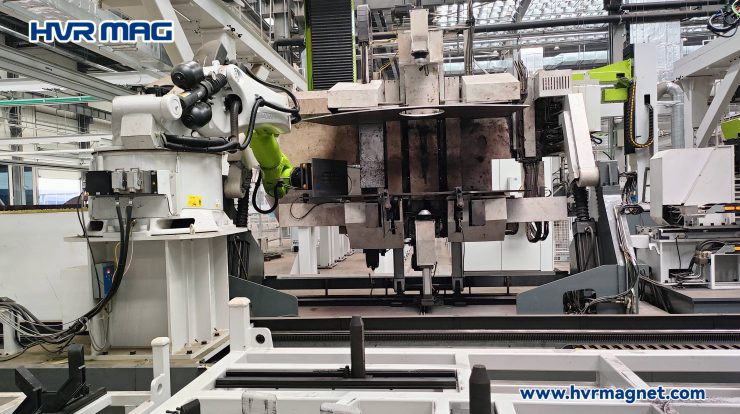

Roboic arms are used in many industrial applications such as assembly, loading/unloading, packaging, sorting, dispensing, sanding, and polishing, They have evolved to become more independent and sophisticated machines that not only share the workspace but are genuinely work partners with human beings.

Pros of Robotic Arms (listed but not limited to)

- They can perform intricate tasks that require a lot of dexterity & cause repetitive stress injury in humans,like heavy lifting duties or handle harmful toxic substances or extremely hot components

- Flexibility – they have the ability to work safely outside of a dedicated work cell means that people can augment the robot’s work (and vice versa), allowing the operations to realize higher productivity without either additional labor or extensive capital investment.

- Increased productivity- increase productivity & reduce labor costs; (Cobots only) no need to add security fence, can work in collaboration with a person on the same area.

- Precision and accuracy- can be programmed to do a lot of different tasks. Well, almost anything you can think of. Manipulation in any position and orientation (for robotic arms with at least 6 axis). You can make the robot do a lot of complex trajectories.

- Free workers up to perform more meaningful tasks

Cons of Robotic Arms in Industry (listed but not limited to)

- Dependant on electric power – as long as the power goes off, it won’t work.

- Requireconstant monitoring – have to be monitored at all times to ensure that they do not get any mechanical faults which would cause them to stall.

- Not creative or innovative – do not have the capacity to be creative or innovative. Robots can only complete tasks as they are instructed to through programming.

- Lack of touch sensitivity, corrosion damage, maintenance.

- Costly Initial installation.