What Is A Pick and Place Robot?

Typically mounted on a stable stand, pick and place robots are strategically positioned to reach different areas to perform work. They speeds up the process of picking up parts or items and placing them in other locations. They handle repetitive tasks while freeing up human workers to focus on more complex work.

How Does A Pick and Place Robot Work?

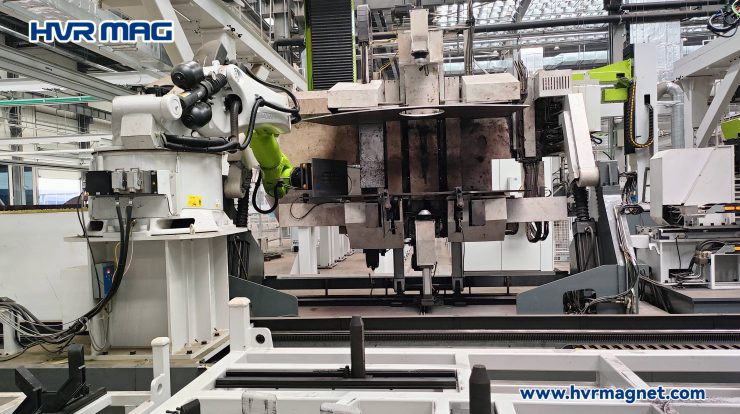

They use advanced vision systems to identify, grasp and move objects from one place to another. The main part that performs the picking and placement is the end-effector of the robotic arm. End-effector enables the robot to interact with the surrounding environment. Once been properly programmed, the robot can pick the part with its gripper and place it to a designated position.

There are different types of robot grippers, like vacuum gripper, mechanical grippers, magnetic grippers, etc. Each type is used in a specific kind of handling applications. Take the magnetic type for example, it’s used when the industrial robot is required to handle ferrous steel parts.

How Are Pick and Place Robots Used in Industrial Automation?

Industrial robots have become commonplace in today’s manufacturing environment to perform simple, repetitive and monotonous tasks which entertains a large work of human power, especially the pick and place type.

With a variety of design options available, pick and place robots can be configured with various end-of-arm tooling options for use in different applications, such as assembly, packaging or bin picking. Here’s a look at a few of the most common applications for pick and place robots and how they’re used.

Assembly – used in assembly applications grab incoming parts from one location, such as a conveyor, and place or affix the part on another piece of the item. The two joined parts are then transported to the next assembly area.

Packaging – used in the packaging process grab items from an incoming source or designated area and place the items in a packaging container.

Bin picking – used in bin picking applications grab parts or items from bins. These pick and place robots typically have advanced vision systems allowing them to distinguish color, shape and size to pick the right items even from bins containing randomly mixed items. These parts or items are then sent to another location for assembly or packaging.

Inspection – used for inspection applications are equipped with advanced vision systems to pick up objects, detect anomalies and remove defective parts or items by placing them in a designated location.

As pick and place robot speed up the process of picking up parts or items and placing them in other locations, various industries will be employing this intelligent manufacturing concept to improve their production rate and overall productivity.