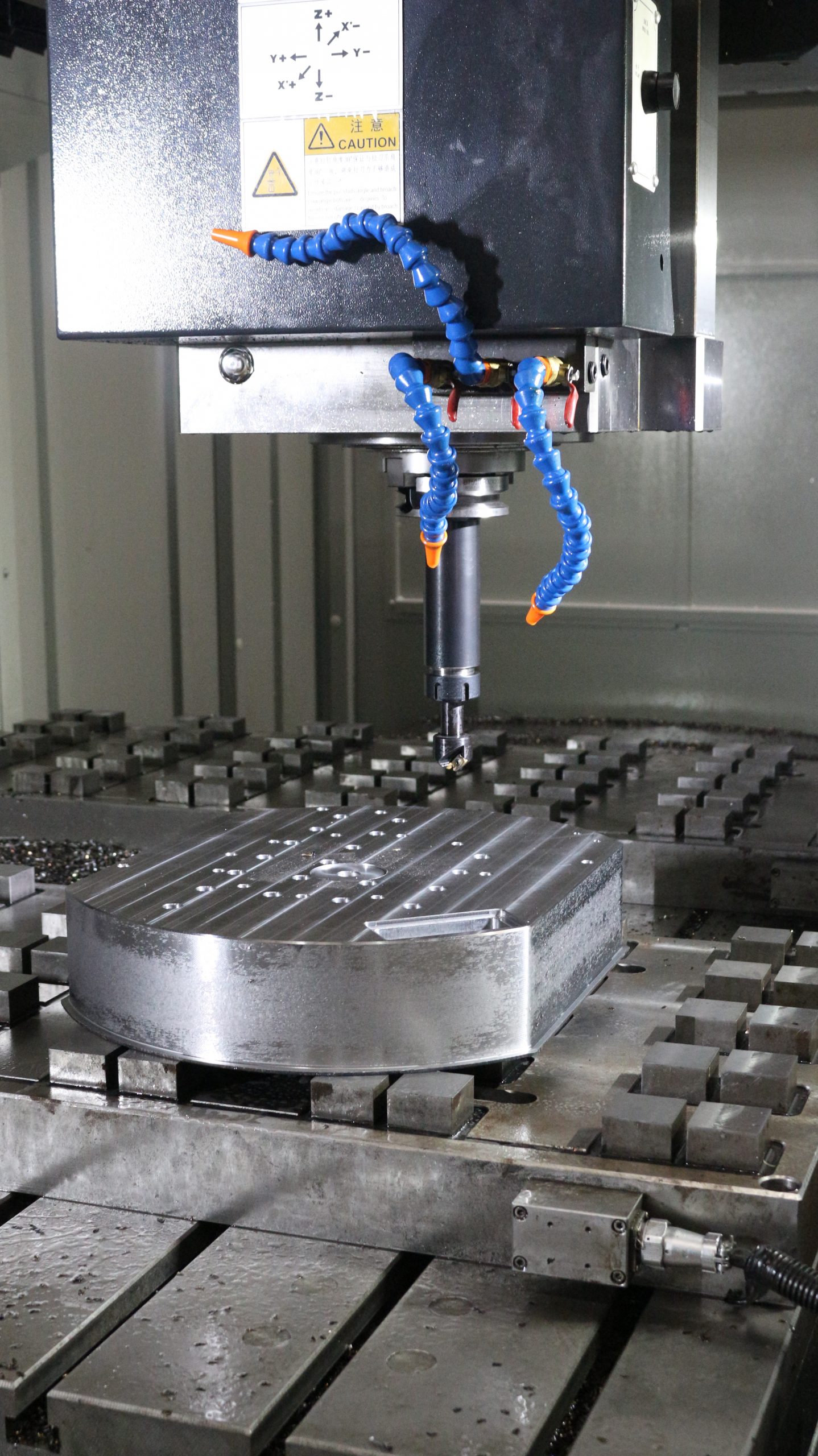

Magnetic workholding is a way of using magnetic force to fixate/clamp the workpiece for specific machining operations like on lathe, grinding machine, milling machine, or cnc machining centers.

Compared to traditional fixturing methods, magnetic workholding not only frees up all five sides of your workpiece so you can machine the multiple profiles in once, but also greatly reduces set up and part change-over time, giving your spindle more time to make chips.

Also it offers a reliable magnetic solution for fabricators who want to grind or mill steel workpieces without damage that can come from mechanical clamping and chuck devices.

The most common way of magnetic workholding is by installation of magnetic chucks on machining tables. Due to the property of magnet chuck, it holds all ferrous materials for general milling or other types of machine operation, helping company to build an efficiency.

As a type of magnetic workholding, electro-permanent magnetic chucks provide a consistent clamping pressure that ensures there is no variation in how tightly or loosely the work piece is held, this hold improves the working safety of the user. The permanent hold also provides accuracy and precision in machining, cutting, drilling, milling, turning and grinding.

Advantages of using magnetic workholding chucks in machining:

- Constant & uniform clamping and full support of workpiece

- Unlike mechanical clamps and vises, no vibration or chatter

- Allow access to multi-side machining of a workpiece – no need to stop and re-position

- Improved safety–electro permanent magnetic technology guarantees a secure and stable hold of the workpiece even in a power outage

- Very efficient since workpieces can be attached/detached by switching operation.

- Energy-saving, since electric power is used momentarily forattaching/detaching workpieces only.

- High accuracy because of no thermal distortion due to heat generatedduring power on.

- No change in the holding power in the event of power failure while the workpiece is being held.

HVR MAG engineers and manufactures magnetic workholding chucks for grinding, machining, milling, turning, EDM, and molding applications. We also offer special magnet chuck designs to meet our customers’ unique application needs. Just tell us your requirements and provide us the working conditions of your machining operation, we’ll tailor design a proper magnetic workholding device for your need.