As the title suggests, this article centers around the story between customized magnetic grippers used for robots, and KUKA, about how they function in the packing line of a workshop that manufactures steel wire for radial tire.

To begin with, let’s learn find out what the function of a robot gripper is.

In the simplest terms, grippers are devices that enable robots to pick up and hold objects. When combined with a collaborative (or ‘cobot’) industrial robotic arm, grippers enable manufacturers to automate key processes, such as inspection, assembly, pick & place and machine tending.

How does magnetic grippers used for robots work?

In robotics, magnet grippers use a magnetized surface to grab metal items. This type of gripper doesn’t usually incorporate fingers or jaws, instead relying on smooth magnetic surfaces for handling. They are common in industries where ferrous parts are being moved along in assembly or packaging line.

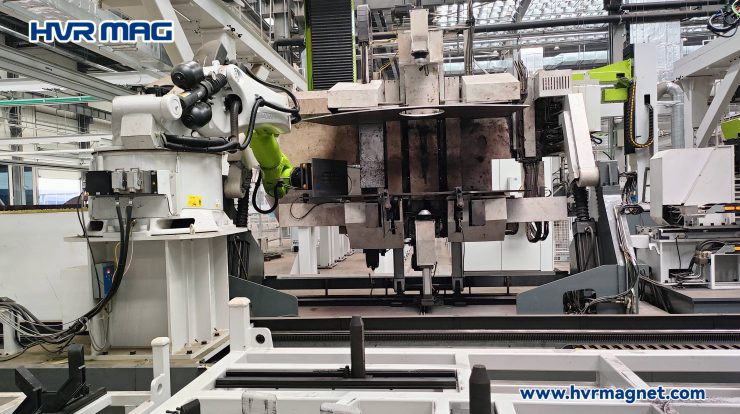

Take the grippers in the following pictures for example, one robot was equipped with one yellow magnetic gripping head, while the other with two magnet heads. Apparently, grabbing 2 spools each time can significantly improves the handling efficiency than the robotic gripper with one gripping head.

One magnetized the deep magnetic flux of these epm magnet grippers, can penetrate through the 2mm thick steel plate to pick up the steel spool.

There’s a special place about the new magnetic gripper used for KUKA robot, that it has a gripping device that can pick up the damp-proof plastic panel, when the spools on it were all been transferred.

HVR MAG Customized Magnetic Grippers Used for KUKA Robots

This gallery shows the different applications of magnet grippers manufactured by HVR MAG, used on KUKA robots in different workshops.

HVR MAG can tailor electro permanent magnets to pick, lift, load, place, transfer of ferrous parts for robot arm and automation line as an end-of arm-tool. The integration of automation magnets and industrial robots in manufacturing process will become the leading trend in automation applications such as transfer/conveyor lines, packaging line, palletising/depalletising systems, pick and place in machine tending etc. Contact us to get a magnetic solution for your manufacturing business now!