Pneumatic magnetic gripper and electric permanent magnet grippers are both steel handling tools fitted to industrial robots. They are both made of NdFeB permanent magnets but are controlled differently.

Features of the electro-permanent magnet gripper

Electro-Permanent Magnets are very energy efficient and only use electricity at the moment of magnetisation and demagnetisation. The electric current changes the direction of the magnetic field of the permanent magnet material inside, using this principle to grip and release the workpiece.

The advantages of electric control are intelligence and convenience. The electro-permanent magnet gripper has no external accessories and can be connected directly to the robot with the power cable. The magnetic strength can be adjusted. It can be customised with a demagnetisation function to prevent the workpiece from being affected by residual magnetism.

Features of the pneumatic magnetic gripper

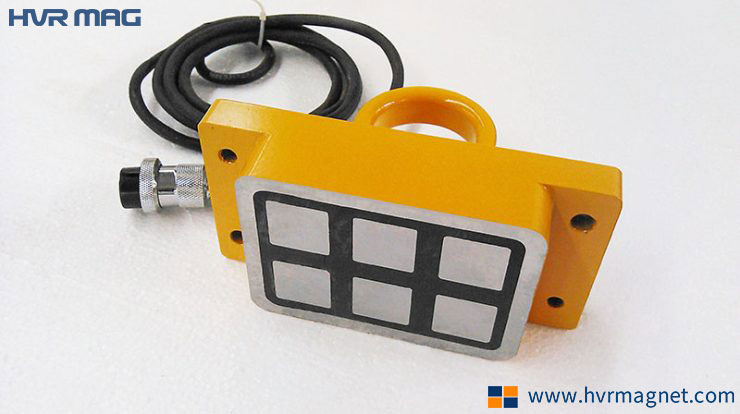

The pneumatic magnetic gripper uses a pneumatic piston to switch between MAG and DEMAG stages. This requires an external cylinder. A sensor inside the pneumatic magnetic gripper identifies the piston position and provides signal feedback to the entire control system of the automation line/robot.

Common advantages of pneumatic magnetic gripper and EPM gripper

- Strong magnetic force. Both are made of NdFeB permanent magnets with a magnetic force of up to 16 kg/cm².

- High efficiency. The powerful magnetic suction combined with the fast control makes both magnetic grippers efficient for sorting, palletizing and other steel handling tasks.

- High safety. As both do not require electricity to maintain magnetism, workpieces will not fall off in the event of an electrical failure. And they do not get hot over long periods of time.

- Low maintenance costs. The magnetic properties of the permanent magnets are very weak and do not require frequent maintenance and replacement.

- Universal use. The same magnetic gripper can grip both steel plates and irregularly shaped or drilled workpieces if the workpieces are of similar weight.

In general, the pneumatic magnetic gripper and the EPM gripper have the same core materials, so the performance is basically the same. However, the differences in control methods and installation requirements are more significant. The electro-permanent magnet has a more streamlined structure and so is easier to install. Pneumatic magnets have cylinders and connecting pipework etc. and require attention to installation conditions. In addition, the magnetic strength of the electric permanent magnets is adjustable and the control method is more intelligent. The magnetic strength of pneumatic magnetic gripper is constant and non-adjustable.

HVR MAG has several ranges of electro-permanent magnetic grippers: EPM Gripper for Articulated Robot, EPM Gripper for Gantry Robot, Welding Magnets for Automation. Magnetic strength, size and shape can be customised. Magnetic grippers not only help you with the gripping, lifting and placing of ferrous parts in automated production lines. They can also be used to hold workpieces on automatic welding machines. Can be loaded on truss robots for handling larger sizes of steel. With the development of “Industry 4.0”, magnetic grippers will be more and more widely used in the automated production of smart factories.

Feel free to contact us for customised magnetic grippers.