What Is A Magnetic End Effector?

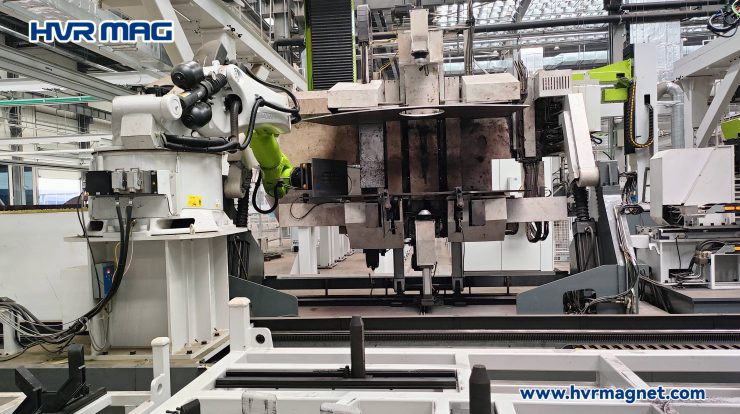

Magnetic end effector, also known as magnetic grippers or robot magnetic end-of-arm tool, is a must-have for robotic pick and place of steel parts, especially in intelligent manufacturing applications.

Magnetic end effector offers a way to handle ferrous workpieces, small or large. Magnetic grippers use a magnetized surface to grab metal items, and are common in industries where sheet metal and steel parts for vehicle manufacturing are being moved along an assembly line.

How Does Magnetic End Effector Work?

It provides safe gripping of ferromagnetic workpieces by using the magnetic force released by electro permanent magnet. Switched on &off by a momentous electric pulse, PLC programmable, it can pick, lift, load, place, transfer of ferrous parts for robot arm and automation line as an end-of arm-tool.

Robot Magnetic End Effectors of Various Shapes & Designs

Typical Applications In Robotics

1. The most ideal solution to transport steel load together with robot and automatice device, such as: lifting steel block, angel steel, steel pipe, vertical lifting, etc..

2.Transport steel load into cutting machine, press machine, shearing machine, welding line, punching machine,etc..

If you’re interested in this type of robot magnetic end effector, and wanna know more about its industrial applications, welcome to visit our product page or you can present your questions to us for further discussion.