When sourcing robot magnetic gripper for automation tasks, many engineers would think of electromagnet, and neglecting the other type EPMagnet. Undoubtedly, the former is more widely known to most people than the latter. Still, we have to make you get acquainted with the EPM magnetic gripper to get the most of your robotic handling efficiency.

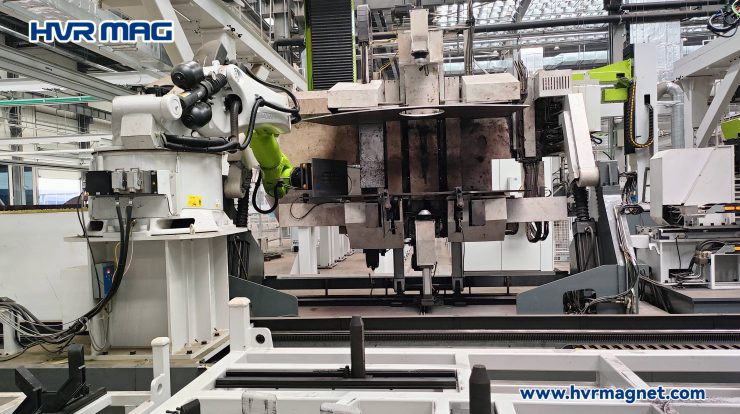

Shown in the following pictures, is a KUKA robot manipulating track plate in a workshop.

What does the robot gripper do?

This robotic arm is responsible for unloading the track plate cut piece off the conveyor line, and then palletise it on designated pallet one by one.

And the gripping device they were using is electromagnetic gripper. So what changed their mind for electro permanent magnet?

Every change has a reason. And the specifics lies in below(according to their feedback):

▶Poor safety performance: once a power failure occurs, there was a risk of dropping plate, causing damage to facilities and products

▶Poor reliability (high fault rate): the short cycle time (5 seconds), makes the temperature of electromagnetic gripper very high, which is more subject to be burned out.

While with HVR MAG‘s EPM robot magnetic gripper, things are greatly different:

✦HEPMP-5715S electro permanent magnet, specifically designed based on all the drawings of their track plates;

✦The magnetic gripping force was calculated by computer simulation and tested via actual processing in workshop.

✦3:1 safety factor; can remain gripping of plate even in a sudden power failure

✦Minor heat generation, only uses electricity in MAG and DEMAG phase to switch the magnetic force on and off;

✦Low calorific value: our EPM use copper wire, unlike electromagnet using Aluminum wire.

✦The short-cycle-time targeted design: including using high-temperature magnet poles, and heat-resistant materials inside the magnet; also taking into account of the heat dissipation problem.

This EPM robot magnetic gripper, manufactured by us, has been put into use for four years, with extremely reliable performance, which is very satisfying to our client. Do you wanna know more about our gripping solution for robotics? Visit our product page to find out more.