Mercedes-Benz has recently announced that it will ensure its passenger cars are carbon neutral along the entire value chain by 2039. It will use its partners’ latest “hydrogen steel” technology materials to make the whole industry chain green.

(Hydrogen steel technology refers to steel produced using green hydrogen energy rather than coking coal)

Automotive giants have announced a new production model to achieve low carbon production. How is low carbon production being implemented across the automotive industry chain, and what is the potential for future development?

Green material selection

When selecting materials for standard components, technical performance and economic factors are mainly considered. At the same time, more attention is paid to material savings and avoiding waste, but little consideration is given to the environmental impact of material selection. The selection of materials for green manufacturing should follow environmental, technical, and economic principles and be comprehensive and rational.

Swedish Steel’s Luleå plant has set a milestone in the global production of zero fossil fuel steel by delivering the first “hydrogen steel” produced using HYBRIT technology to Volvo. Volvo plans to use the low-CO2-emitting metal for its concept cars. Swedish Steel intends to supply the market with zero fossil fuel “hydrogen steel” on a commercial scale from 2026.

Technological innovations

Green manufacturing in manufacturing automotive components and product assembly is a complex engineering issue. Through the introduction of advanced energy-saving and environmentally-friendly equipment, green production process improvement, optimization of the decision-making system, and end-of-pipe non-hazardous treatment and recycling, the consumption of resources and the negative impact on the environment are minimized.

HVR helps the low-carbon automotive industry

How does the EPM lifting system help the automotive industry produce lower carbon dioxide? Electro-permanent magnets only need electricity for magnetization and demagnetism, and they can save 95% of electricity.

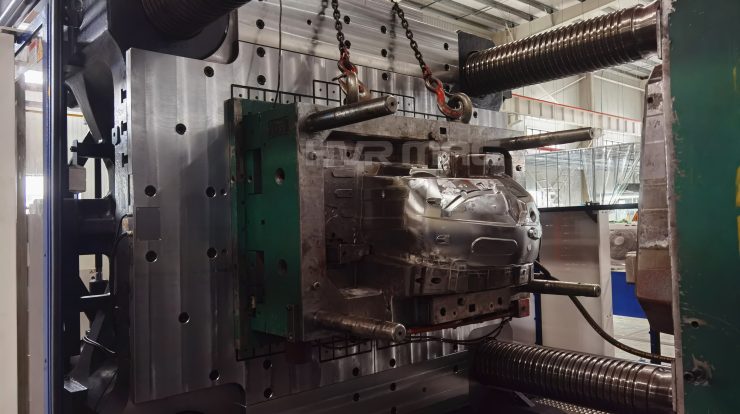

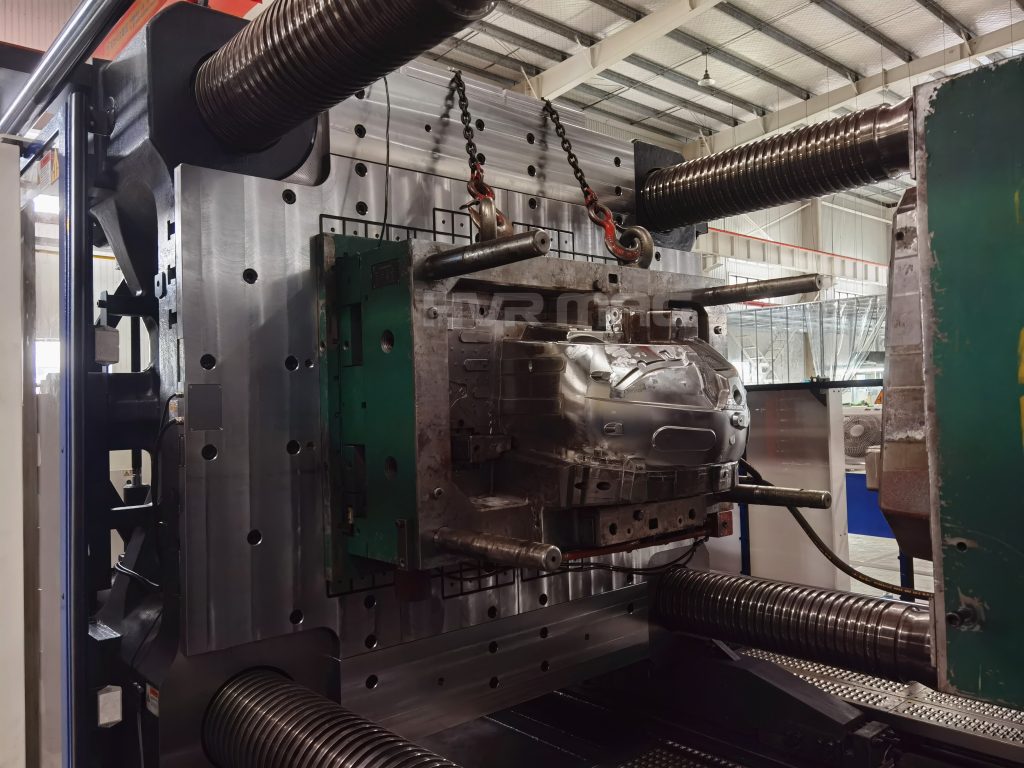

The automotive and other industries use injection molding machines to process shell parts, whether interior or exterior parts, to provide qualified products in parallel, in sets, and on time for different models. The interval between mold changes will determine production efficiency, delivery lead times, and effective return on investment. The magnetic quick-change system can quickly load and unload molds in one minute, reducing mold change times significantly.

Thin steel sheets are often used in the production of automobiles, and spreader tools are used to transport the sheet to the machine for cutting. The factory has strict requirements for sheet steel, such as a flat, smooth surface with no cracks or other defects. However, the traditional way of lifting thin plates does not prevent them from being bumped or deformed. The electro-permanent magnet lifter supports the lifting of lighter gauge steel plates. When lifting thin plates, it can lift single thin plates of 1.5mm-6mm in thickness at one time, making sure that they do not adhere to the second plate and using multi-point adsorption to minimize lifting damage to thin plates.

In automotive processing manufacturing, robots are used for arc welding, spot welding, laser welding, laser cutting, machine tool loading, unloading, forging, stamping, assembly, sorting, etc. Each process is carried out throughout, with different industrial robots to complete various functions. For sorting, loading, unloading, handling, and other operations, the electro-permanent magnetic gripper adsorbs workpieces evenly by magnetic force, without dropping or damaging them, and the rapid translation and turning action adapts to different workpieces and working conditions. This improves the efficiency and core competitiveness of your company!

Contact us now to make your company green!